Back

Purpose: ingredients from light-induced degradation. For many years, titanium dioxide (TiO2), classified as E171 when used as a pigment in foods, has been the preferred opacifier in the industry. However, the use of TiO2 as a food additive has been suspended in Europe, requiring companies to explore alternative materials. Mineral-based opacifiers such as calcium carbonate or magnesium carbonate have lower opacity than TiO2 but are currently being used as an alternative to TiO2. Formulators have achieved high opacity through optimization of the film coating within these mineral-containing systems1. Our recent studies have shown that the alkaline nature of minerals may affect the color of naturally derived pigments. In addition, they may interact with some active ingredients. The current study aimed to evaluate the opacity of a novel fully formulated Nutrafinish® Label Friendly System using natural, plant-based opacifiers.

Methods: Nutrafinish film coating systems are developed specifically for nutritional and dietary supplement products and the following formulations were used in this study. Nutrafinish high opacity and label friendly formulations were optimized to deliver high levels of opacity using calcium carbonate and a natural opacifier, respectively. Their performance will be compared to a TiO2-containing formulation. Nutrafinish formulations were coated on 3.0 kg of multivitamin tablets (1000 mg) using a fully perforated 15″ side-vented coating pan (Labcoat II, O’Hara Technologies Inc., Canada) to a 5% weight gain (WG) with samples taken at 3%, 4% and 5% WG to evaluate opacity.

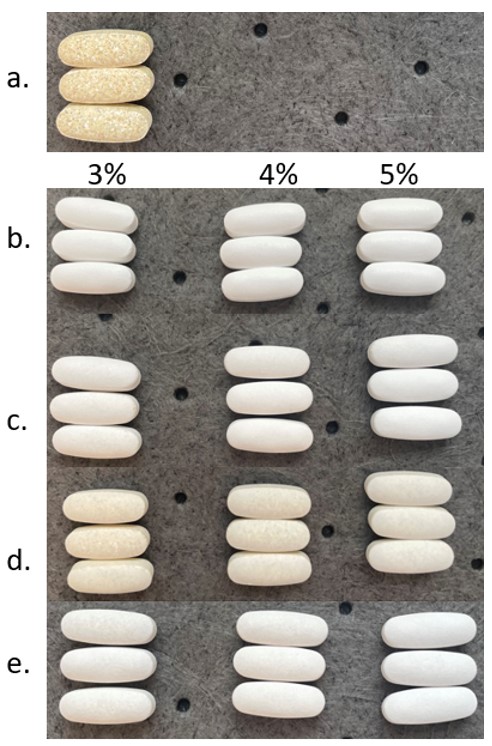

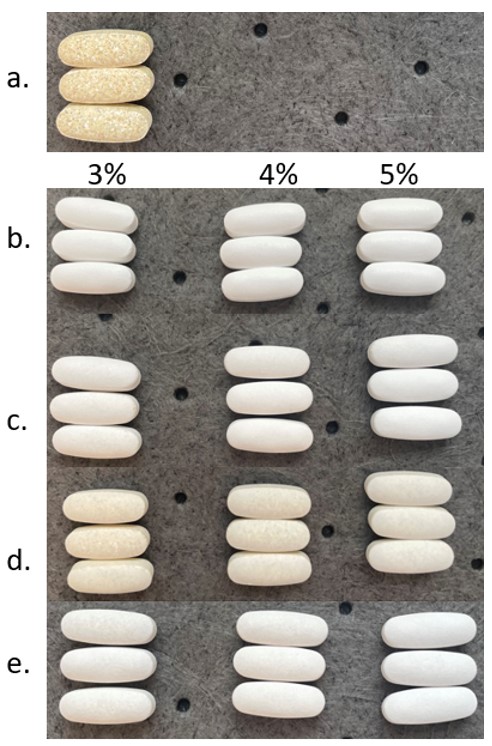

Results: Uncoated and coated multivitamin tablets at 3, 4, and 5% coating weight gain are shown in Figure 1. Nutrafinish TiO2 showed the best opacity with uniform coverage at 3% WG (Figure 1 b). The best TiO2 free option (Nutrafinish high opacity) uses calcium carbonate as the opacifier, and uniformity can be achieved at 3% WG (Figure 1 c). When TiO2 was directly replaced with a plant-based opacifier, the opacity was significantly decreased, and the coating was unable to hide the spotting of multivitamin tablets even at 5% WG (Figure 1 d). However, the novel optimized Nutrafinish Label Friendly formulation using a natural opacifier shows good opacity that can be achieved at 3-4% WG, without the use of calcium carbonate. (Figure 1 e). Figure 2 shows multivitamins coated with Nutrafinish systems containing anthocyanin. Nutrafinish containing calcium carbonate has a high pH of ~ 8.5 which causes the color of the film coating to turn brown. Nutrafinish Label Friendly has a neutral, pH of ~ 7 which allows it to develop a vibrant red color. This demonstrates the advantage associated with calcium carbonate-free opacifiers for the color development of film coating systems with natural pigments.

Conclusion: A novel Nutrafinish Label Friendly coating was developed using a naturally derived plant-based opacifier that replaced commonly used mineral components such as TiO2 or calcium carbonate. This system was designed specifically for the nutritional and dietary supplement market to meet consumer demand for a clean-label choice. The advantage of a naturally derived opacifier within coating systems using non-synthetic pigments such as anthocyanins was demonstrated, resulting in enhanced and vivid coloring compared to mineral-based formulations.

References: 1. Badger S, Ghimire, M and Rajabi-Siahboomi, A. Impact of Opacifier Type in a Film Coating Formulation on Photostability of Tablet Ingredients. AAPS 360 (2021). T1430-07-37.

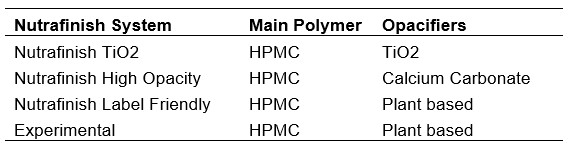

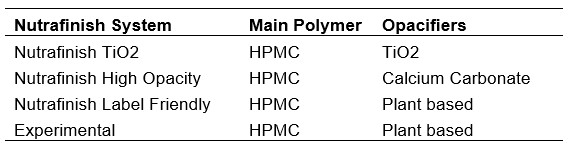

Table 1: Nutrafinish Formulations Evaluated

Figure 1: (a) Uncoated Multivitamin, (b) Multivitamin Tablets coated with Nutrafinish TiO2, (c) Nutrafinish High Opacity, (d) Experimental, and (e) Nutrafinish Label Friendly.

Figure 2: Multivitamin Tablets Coated with (a) Nutrafinish Label Friendly and (b) Nutrafinish High Opacity Containing Anthocyanins as Pigments

Formulation and Delivery - Chemical - Formulation

Category: Poster Abstract

(W1130-03-14) Development and Evaluation of a Label Friendly Film Coating System Containing Naturally Derived Opacifier

Wednesday, October 19, 2022

11:30 AM – 12:30 PM ET

- MG

Manish Ghimire, Ph.D.

Colorcon, Inc.

Harleysville, Pennsylvania, United States - TM

Tara Moffa, BS

Colorcon, Inc.

Harleysville, Pennsylvania, United States

Presenting Author(s)

Main Author(s)

Purpose: ingredients from light-induced degradation. For many years, titanium dioxide (TiO2), classified as E171 when used as a pigment in foods, has been the preferred opacifier in the industry. However, the use of TiO2 as a food additive has been suspended in Europe, requiring companies to explore alternative materials. Mineral-based opacifiers such as calcium carbonate or magnesium carbonate have lower opacity than TiO2 but are currently being used as an alternative to TiO2. Formulators have achieved high opacity through optimization of the film coating within these mineral-containing systems1. Our recent studies have shown that the alkaline nature of minerals may affect the color of naturally derived pigments. In addition, they may interact with some active ingredients. The current study aimed to evaluate the opacity of a novel fully formulated Nutrafinish® Label Friendly System using natural, plant-based opacifiers.

Methods: Nutrafinish film coating systems are developed specifically for nutritional and dietary supplement products and the following formulations were used in this study. Nutrafinish high opacity and label friendly formulations were optimized to deliver high levels of opacity using calcium carbonate and a natural opacifier, respectively. Their performance will be compared to a TiO2-containing formulation. Nutrafinish formulations were coated on 3.0 kg of multivitamin tablets (1000 mg) using a fully perforated 15″ side-vented coating pan (Labcoat II, O’Hara Technologies Inc., Canada) to a 5% weight gain (WG) with samples taken at 3%, 4% and 5% WG to evaluate opacity.

Results: Uncoated and coated multivitamin tablets at 3, 4, and 5% coating weight gain are shown in Figure 1. Nutrafinish TiO2 showed the best opacity with uniform coverage at 3% WG (Figure 1 b). The best TiO2 free option (Nutrafinish high opacity) uses calcium carbonate as the opacifier, and uniformity can be achieved at 3% WG (Figure 1 c). When TiO2 was directly replaced with a plant-based opacifier, the opacity was significantly decreased, and the coating was unable to hide the spotting of multivitamin tablets even at 5% WG (Figure 1 d). However, the novel optimized Nutrafinish Label Friendly formulation using a natural opacifier shows good opacity that can be achieved at 3-4% WG, without the use of calcium carbonate. (Figure 1 e). Figure 2 shows multivitamins coated with Nutrafinish systems containing anthocyanin. Nutrafinish containing calcium carbonate has a high pH of ~ 8.5 which causes the color of the film coating to turn brown. Nutrafinish Label Friendly has a neutral, pH of ~ 7 which allows it to develop a vibrant red color. This demonstrates the advantage associated with calcium carbonate-free opacifiers for the color development of film coating systems with natural pigments.

Conclusion: A novel Nutrafinish Label Friendly coating was developed using a naturally derived plant-based opacifier that replaced commonly used mineral components such as TiO2 or calcium carbonate. This system was designed specifically for the nutritional and dietary supplement market to meet consumer demand for a clean-label choice. The advantage of a naturally derived opacifier within coating systems using non-synthetic pigments such as anthocyanins was demonstrated, resulting in enhanced and vivid coloring compared to mineral-based formulations.

References: 1. Badger S, Ghimire, M and Rajabi-Siahboomi, A. Impact of Opacifier Type in a Film Coating Formulation on Photostability of Tablet Ingredients. AAPS 360 (2021). T1430-07-37.

Table 1: Nutrafinish Formulations Evaluated

Figure 1: (a) Uncoated Multivitamin, (b) Multivitamin Tablets coated with Nutrafinish TiO2, (c) Nutrafinish High Opacity, (d) Experimental, and (e) Nutrafinish Label Friendly.

Figure 2: Multivitamin Tablets Coated with (a) Nutrafinish Label Friendly and (b) Nutrafinish High Opacity Containing Anthocyanins as Pigments