Formulation and Delivery – Biomolecular

Prologue: Science-Based Formulation and Process Development of Biologicals: Physical Chemical and Analytical Aspects

-

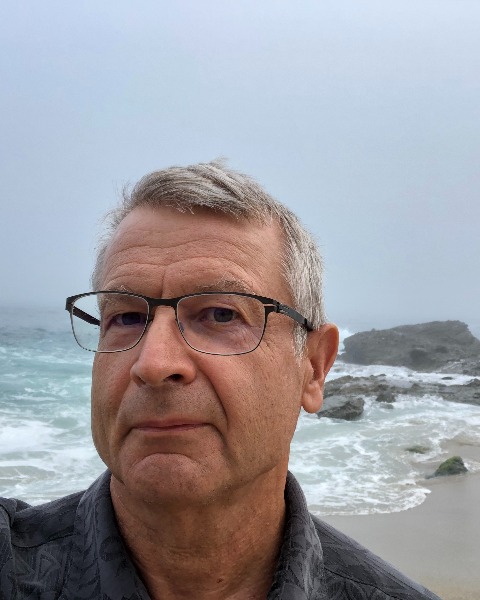

Evgenyi Shalaev, PhD

Distinguished Research Fellow

Abbvie

Irvine, California

Prologue Speaker(s)

Biotech drugs, such as antibodies, protein/drug conjugates, vaccines, and gene therapy products, represent the fastest growing segment in the pharmaceutical industry. While these drugs deliver breakthrough in treatment of multiple diseases, there are significant scientific and technical challenges encountered during their development. In particular, stability of both drug substance (DS) and drug product (DP) represents a key factor in commercialization of any pharmaceutical and biopharmaceutical product. To ensure product stability and manufacturability, excipients are usually added to DS and DP formulations, and selection of excipient’s type and amount is an integral part of drug development process. These critical aspects of DS and DP development are covered in symposium “Theme 2: Advances in Engineering Technologies for Drug Substance and Enabling Drug Product”, with presentations devoted to surfactants and other pharmaceutical excipients, advanced analytical techniques for characterization of frozen and freeze-dried materials, and stability prediction of solid biological formulations.

Drug substances are usually stored as frozen solutions, while many biological DPs are developed as freeze-dried formulations to ensure stability during storage and shipping. The prologue presentation covers physical chemical principles of stability of both frozen solutions and solid pharmaceutical materials, including protein/ice interaction, acid-base relationships, crystallization of excipients and other phase transition, and the role of water clusters in catalysis of various degradative processes. To address a popular pharmaceutical topic of molecular mobility/stability relationships for amorphous pharmaceuticals, temperature dependences of various types of molecular mobility are compared with these for degradative processes in amorphous solids as well as with chemical reactions in solution.

For rationale selection of excipients, including surfactants, bulking agents, and cryo/lyoprotectors, it would be essential to understand their phase behavior under representative manufacturing and storage conditions. In this respect, phase diagrams and solid-liquid state diagrams, which describe phase composition and relationships between crystalline, liquid crystalline, and amorphous phases as a function of temperature and overall composition of a particular system, represent a very valuable tool for formulation and process development. Such diagrams are constructed using data from thermal analytical (such as DSC), diffraction, and spectroscopic techniques. The presentation includes examples of phase diagrams of excipient/water systems, which are studied with synchrotron X-ray diffraction and small-angle neutron scattering methods.

While the phase and state diagrams represent thermodynamic and certain kinetic aspects of excipient/solvent/drug phase relationships, they do not necessarily provide a comprehensive description of behavior of a formulation during pharmaceutical manufacture. To connect the fundamental knowledge of phase transitions, such as crystallization, with the real manufacturing conditions, combination of computer modeling and process analytical technology (PAT) tools would be essential. Selected PAT tools for freeze-drying are considered in the presentation.

Recognizing that it would be impossible to cover all these aspects in 30-min presentation, only a few selected topics are considered in some details, while key (subjective) references on these subjects are provided.

Learning Objectives:

- Appreciate the scientific complexity of DS and DP development

- Understand general scientific principles for efficient and predictable development of formulations and manufacturing processes

- Find literature sources to address specific technical issues encountered during DS and DP development