Back

Purpose: Magnesium stearate (MgSt) is perhaps one of the most frequently used lubricants in tablet formulation due to its superior lubrication capacity, yet it could also negatively affect critical quality attributes of pharmaceutical products. For instance, the basic impurity, such as magnesium oxide, could form magnesium salt with acidic APIs. In this study, we provided a rather comprehensive evaluation on another two FDA-approved metallic stearates, sodium stearate (NaSt) and calcium stearate (CaSt), as alternative tablet lubricants. The primary objective of the present study is to comparatively evaluate the physicochemical properties and lubrication efficiency of three metallic stearates. In addition, it was also aimed to specify the most influential factor for ranking and differentiating the lubricity of various lubricants using principal component analysis.

Methods: Materials NaSt and CaSt were purchased from Acme-Hardesty Co. (Blue Bell, PA). MgSt was obtained from Mallinckrodt (St. Louis, MO). Mannitol for tablet compaction studies was purchased from Roquette America Inc. (Gurnee, IL). Physicochemical characterization Particle size distributions of lubricants were measured using a laser diffraction particle size analyzer. Specific surface area was analyzed using Micromeritics TriStar 3000 automatic physisorption analyzer operated in 11 points Brunauer-Emmett-Teller (BET) model. Particle morphology was examined using Quanta FEG 250F environmental scanning electron microscopy. Water sorption was studied using Q5000SA Dynamic Vapor Sorption Tablet Compaction The powder compaction studies were conducted using a Huxley-Bertram compaction simulator, with 9.525 mm round flat-face tooling with a tablet target weight of 300 mg at the targeted stresses ranging from 80 MPa to 400 MPa. Two compression speeds were used in the current study. Tablet tensile strength (TS), pressure transmission ratio (PTR), unit ejection force (UEF), and friction coefficient (𝜇𝜇) were analyzed for lubricity evaluation.

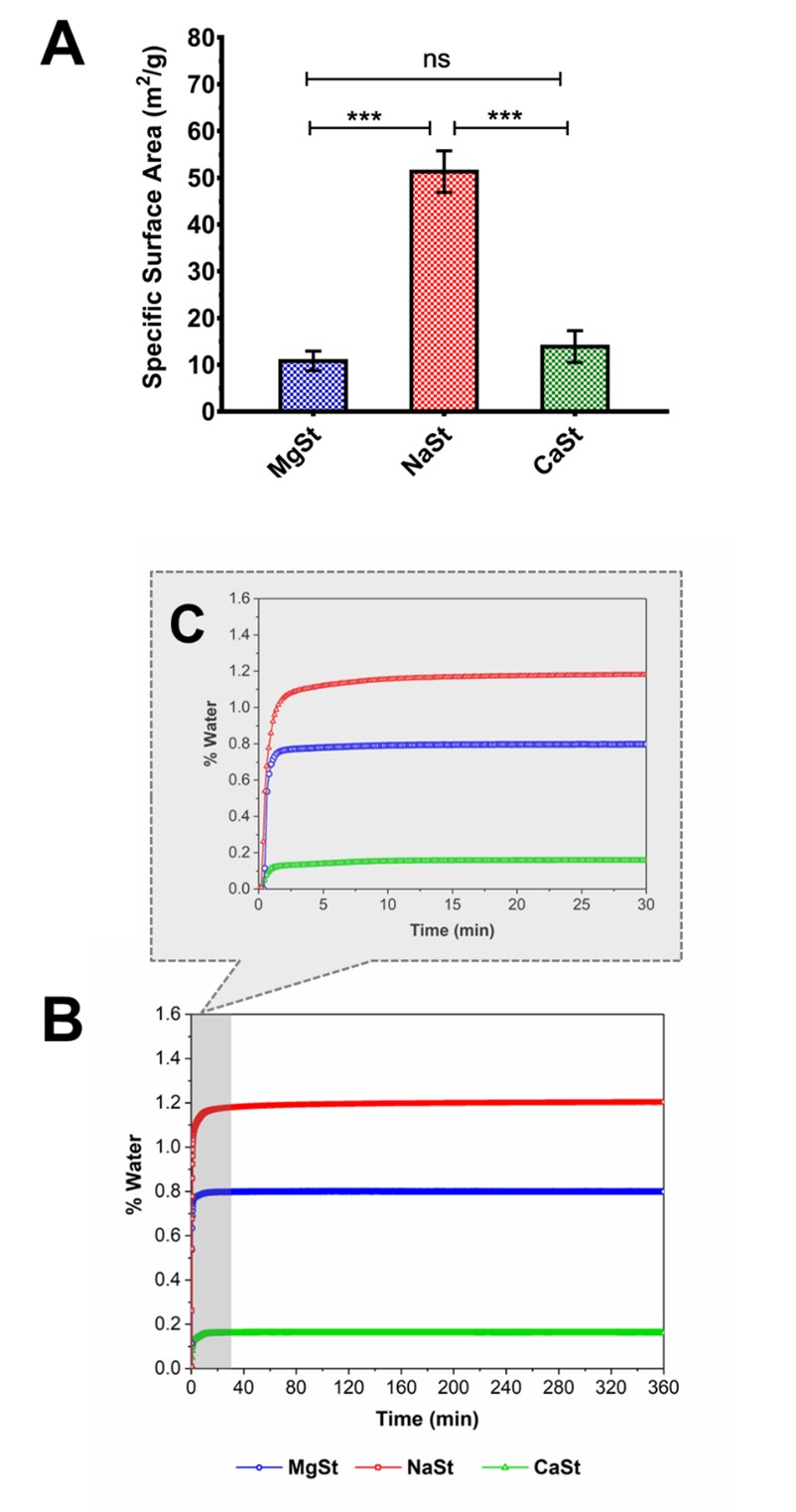

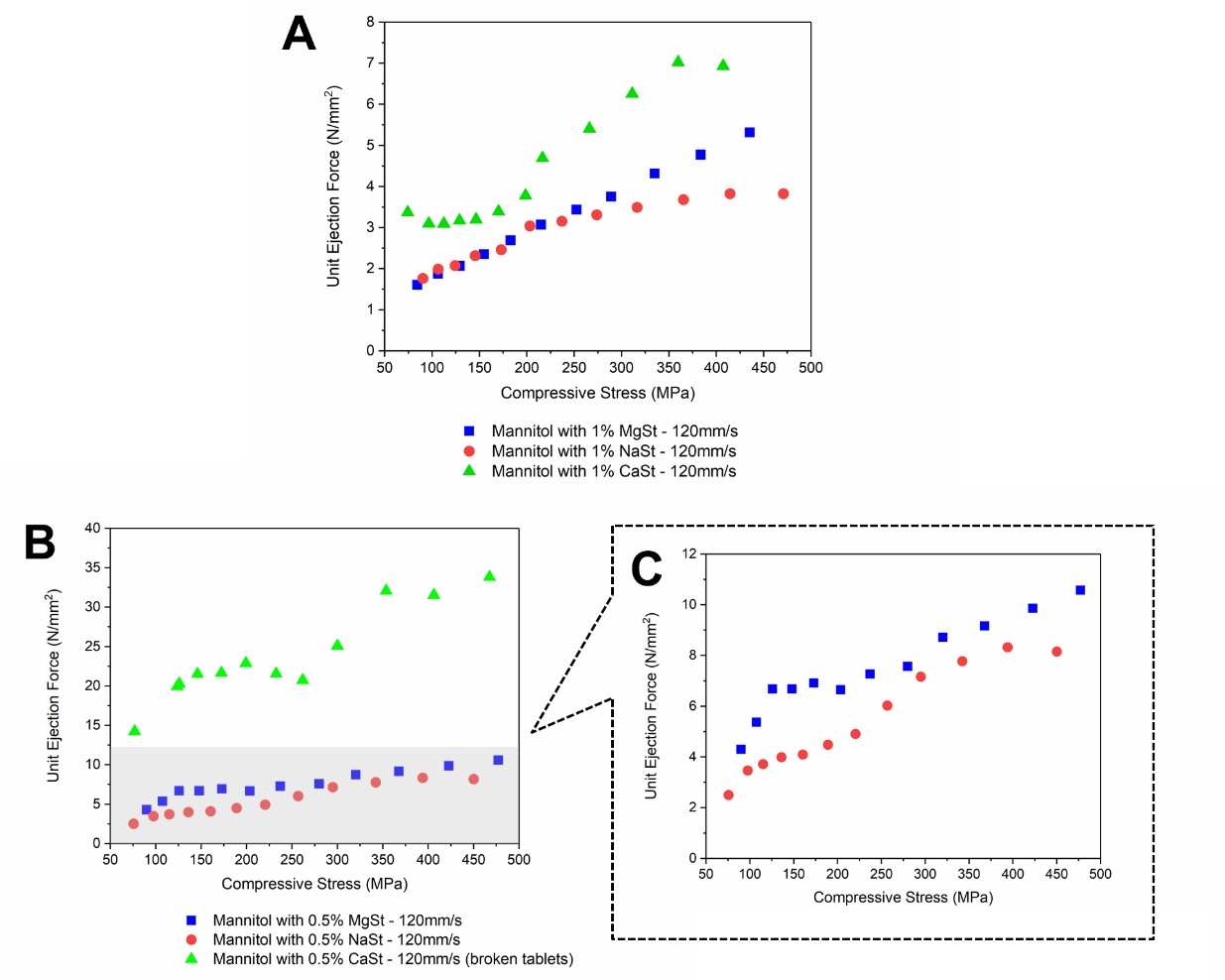

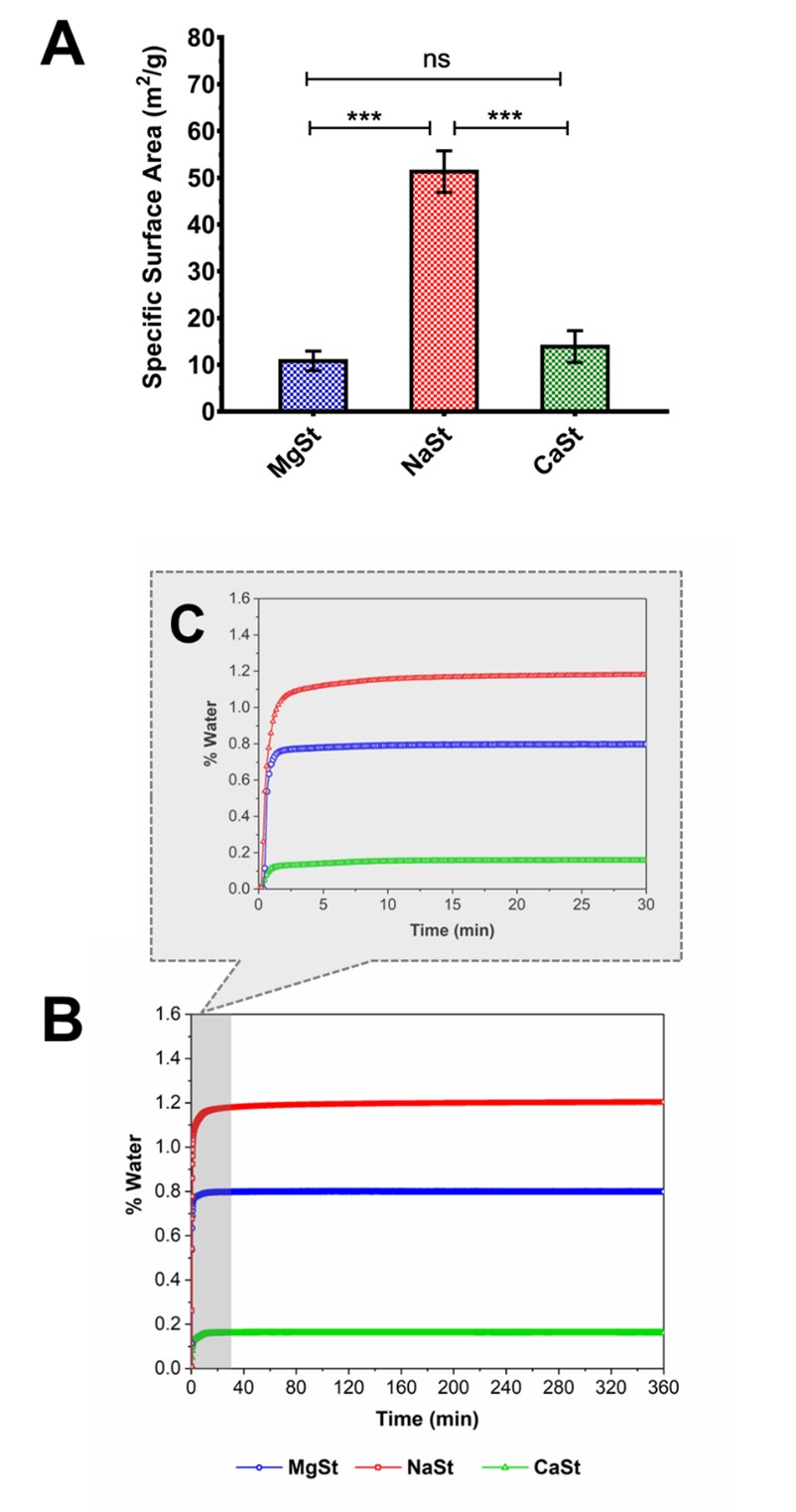

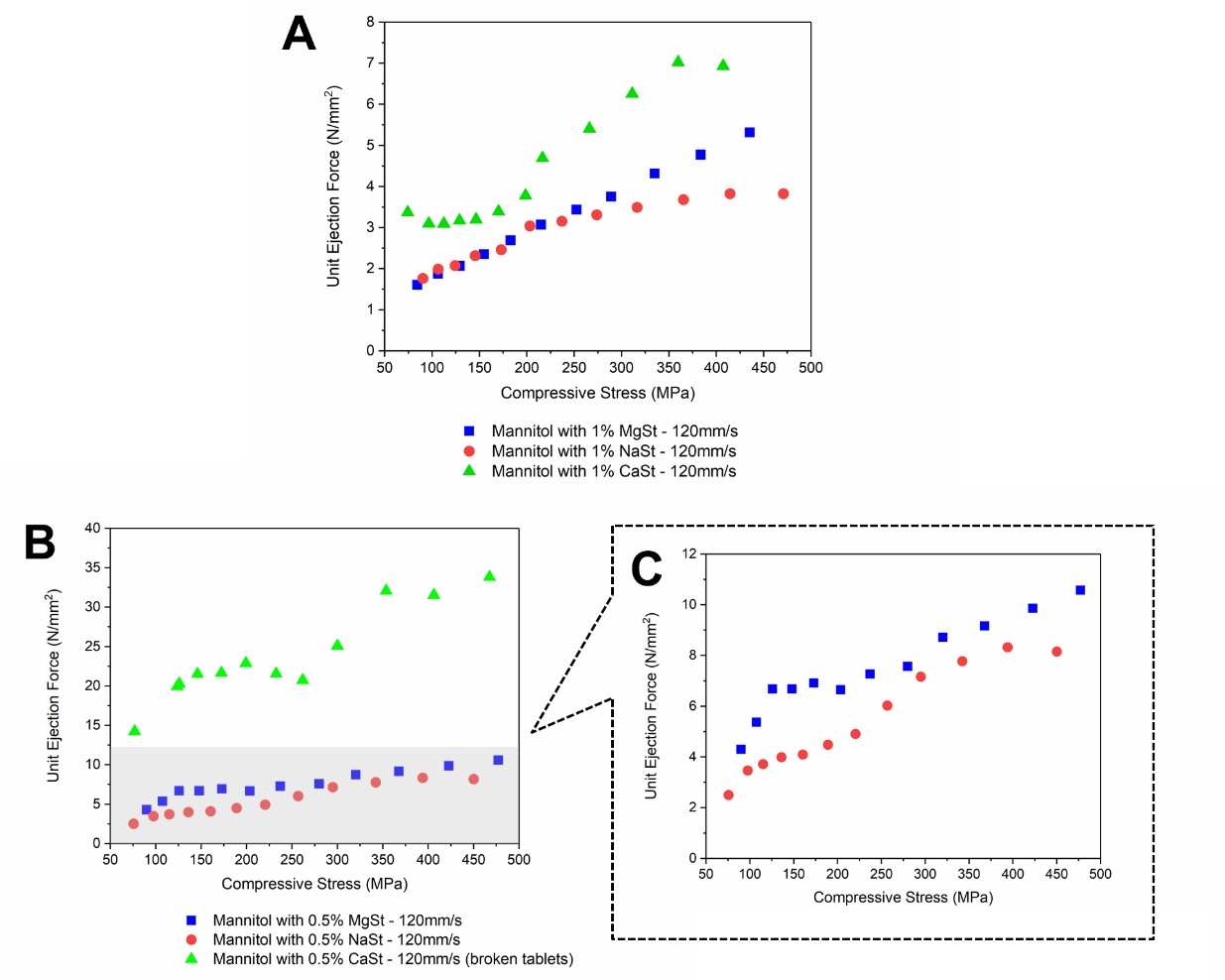

Results: Properties of metallic stearates The value of Dx50 for NaSt, CaSt, and MgSt was 8.05 µm, 9.05 µm, and 7.78 µm. The visualizations in the SEM micrograph agreed with the particle size results that the majority portions of all three lubricants have small particle sizes below 30 µm. In addition, particle morphologies of MgSt and CaSt exhibited both irregular morphology with a flake-like shape. In contrast, the NaSt manifested non-spherical granular-like structure, diminishing the lamellar characteristics. Amongst the three metallic stearates, NaSt showed the largest specific surface area (over 50 m2/g), which was approximately 5 times larger than that of the other two stearates. Tablet Compaction three lubricants had similar impacts on the mechanical strength of tablets, the tablet breakage was observed for the tablet containing 0.5% CaSt at low and high compaction speeds due to its insufficient lubrication capacity. Based on the PTR, UEF, and μej, excellent lubrication performance for formulations containing MgSt or NaSt was confirmed. Notably, the UEF of the formulation containing 0.5% NaSt was equivalent to that of tablets with 1% MgSt even at high compression speed, suggesting that NaSt had the superior lubrication effect possibly due to its large surface area and granular-like morphology. Multivariate Analyses – PCA In the PCA, the first two components captured over 98% of the variation in describing lubrication efficiency. Moreover, the first principal component (PC1) described over 94% of the variation in the data and therefore made the most significant contribution to the lubricity. According to the loading plot of PC1, the most predominant factor among all the parameters is UEF which could be used as a single descriptor to delineate the lubrication efficiency for different lubricants.

Conclusion: The results revealed that NaSt could be an excellent alternative to MgSt to act as an effective lubricant in tablet formulations. In addition, the PCA results showed that the UEF could be applied as a straightforward descriptor to differentiate the performance of different lubricants. In conclusion, the findings of this investigation should provide practical information and feasible methodologies to readily determine the capacity of lubricants and to sensibly select alternative lubricants for pharmaceutical tablet formulations.

References:

Acknowledgements:

Figure 1. BET specific surface area (A) of pure MgSt (blue), NaSt (red), and CaSt (green); Water sorption curves of pure MgSt (blue), pure NaSt (red), and pure CaSt (green) at 40 °C/75% RH over the period of 360 min (B) and 30 min (C) respectively.

Figure 1. BET specific surface area (A) of pure MgSt (blue), NaSt (red), and CaSt (green); Water sorption curves of pure MgSt (blue), pure NaSt (red), and pure CaSt (green) at 40 °C/75% RH over the period of 360 min (B) and 30 min (C) respectively.

Figure 2 Effects of adding 1% (A) and 0.5% (B,C) metallic stearates as lubricants on unit ejection force at 120mm/s compaction speed; MgSt (blue), NaSt (red), and CaSt (green)

Figure 2 Effects of adding 1% (A) and 0.5% (B,C) metallic stearates as lubricants on unit ejection force at 120mm/s compaction speed; MgSt (blue), NaSt (red), and CaSt (green)

Category: Poster Abstract

(T1530-07-42) Application of Alternative Metallic Stearates as Lubricants in Pharmaceutical Tablets

Tuesday, October 18, 2022

3:30 PM – 4:30 PM ET

Haichen Nie, PhD

Associate Principal Scientist

Merck & Co.

West Point, Pennsylvania, United States- DY

Dongyue Yu, Ph.D.

University of Maryland Baltimore

BALTIMORE, Maryland, United States

Presenting Author(s)

Main Author(s)

Purpose: Magnesium stearate (MgSt) is perhaps one of the most frequently used lubricants in tablet formulation due to its superior lubrication capacity, yet it could also negatively affect critical quality attributes of pharmaceutical products. For instance, the basic impurity, such as magnesium oxide, could form magnesium salt with acidic APIs. In this study, we provided a rather comprehensive evaluation on another two FDA-approved metallic stearates, sodium stearate (NaSt) and calcium stearate (CaSt), as alternative tablet lubricants. The primary objective of the present study is to comparatively evaluate the physicochemical properties and lubrication efficiency of three metallic stearates. In addition, it was also aimed to specify the most influential factor for ranking and differentiating the lubricity of various lubricants using principal component analysis.

Methods: Materials NaSt and CaSt were purchased from Acme-Hardesty Co. (Blue Bell, PA). MgSt was obtained from Mallinckrodt (St. Louis, MO). Mannitol for tablet compaction studies was purchased from Roquette America Inc. (Gurnee, IL). Physicochemical characterization Particle size distributions of lubricants were measured using a laser diffraction particle size analyzer. Specific surface area was analyzed using Micromeritics TriStar 3000 automatic physisorption analyzer operated in 11 points Brunauer-Emmett-Teller (BET) model. Particle morphology was examined using Quanta FEG 250F environmental scanning electron microscopy. Water sorption was studied using Q5000SA Dynamic Vapor Sorption Tablet Compaction The powder compaction studies were conducted using a Huxley-Bertram compaction simulator, with 9.525 mm round flat-face tooling with a tablet target weight of 300 mg at the targeted stresses ranging from 80 MPa to 400 MPa. Two compression speeds were used in the current study. Tablet tensile strength (TS), pressure transmission ratio (PTR), unit ejection force (UEF), and friction coefficient (𝜇𝜇) were analyzed for lubricity evaluation.

Results: Properties of metallic stearates The value of Dx50 for NaSt, CaSt, and MgSt was 8.05 µm, 9.05 µm, and 7.78 µm. The visualizations in the SEM micrograph agreed with the particle size results that the majority portions of all three lubricants have small particle sizes below 30 µm. In addition, particle morphologies of MgSt and CaSt exhibited both irregular morphology with a flake-like shape. In contrast, the NaSt manifested non-spherical granular-like structure, diminishing the lamellar characteristics. Amongst the three metallic stearates, NaSt showed the largest specific surface area (over 50 m2/g), which was approximately 5 times larger than that of the other two stearates. Tablet Compaction three lubricants had similar impacts on the mechanical strength of tablets, the tablet breakage was observed for the tablet containing 0.5% CaSt at low and high compaction speeds due to its insufficient lubrication capacity. Based on the PTR, UEF, and μej, excellent lubrication performance for formulations containing MgSt or NaSt was confirmed. Notably, the UEF of the formulation containing 0.5% NaSt was equivalent to that of tablets with 1% MgSt even at high compression speed, suggesting that NaSt had the superior lubrication effect possibly due to its large surface area and granular-like morphology. Multivariate Analyses – PCA In the PCA, the first two components captured over 98% of the variation in describing lubrication efficiency. Moreover, the first principal component (PC1) described over 94% of the variation in the data and therefore made the most significant contribution to the lubricity. According to the loading plot of PC1, the most predominant factor among all the parameters is UEF which could be used as a single descriptor to delineate the lubrication efficiency for different lubricants.

Conclusion: The results revealed that NaSt could be an excellent alternative to MgSt to act as an effective lubricant in tablet formulations. In addition, the PCA results showed that the UEF could be applied as a straightforward descriptor to differentiate the performance of different lubricants. In conclusion, the findings of this investigation should provide practical information and feasible methodologies to readily determine the capacity of lubricants and to sensibly select alternative lubricants for pharmaceutical tablet formulations.

References:

Acknowledgements:

Figure 1. BET specific surface area (A) of pure MgSt (blue), NaSt (red), and CaSt (green); Water sorption curves of pure MgSt (blue), pure NaSt (red), and pure CaSt (green) at 40 °C/75% RH over the period of 360 min (B) and 30 min (C) respectively.

Figure 1. BET specific surface area (A) of pure MgSt (blue), NaSt (red), and CaSt (green); Water sorption curves of pure MgSt (blue), pure NaSt (red), and pure CaSt (green) at 40 °C/75% RH over the period of 360 min (B) and 30 min (C) respectively. Figure 2 Effects of adding 1% (A) and 0.5% (B,C) metallic stearates as lubricants on unit ejection force at 120mm/s compaction speed; MgSt (blue), NaSt (red), and CaSt (green)

Figure 2 Effects of adding 1% (A) and 0.5% (B,C) metallic stearates as lubricants on unit ejection force at 120mm/s compaction speed; MgSt (blue), NaSt (red), and CaSt (green)