Back

Purpose: Diet-induced obesity has become a serious global health problem associated with an increased risk of developing type-2 diabetes, hypertension, atherosclerosis, myocardial infarction, non-alcoholic fatty liver disease, chronic kidney disease, cerebrovascular disease, and cancer [1,2]. Currently, the FDA-approved therapeutic strategies for weight loss include Orlistat, Fenfluramine, and Lorcaserin, but some of them are delisted due to their severe adverse effects [3]. For example, Orlistat was issued a warning due to its serious gastrointestinal adverse effects, and liver failure. Other anti-obesity drugs such as fenfluramine and rimonabant are withdrawn from the market due to their severe side effects such as mood disorders and cardiovascular risks. As an alternative to anti-obesity drugs, bariatric surgery such as Sleeve gastrectomy and Roux-en-Y gastric surgery were found to be more effective. However, it is expensive and associated with an increased risk of post-surgical complications. Therefore, there is an urgent need to develop safe, effective, and personalized therapies for the early prevention and treatment of overweight and obesity. Capsaicin is the principal ingredient of natural chili peppers, responsible for its pungent flavor [4]. Many studies have revealed the beneficial effects of capsaicin such as anti-inflammatory, antioxidant, antiobesity, and anticancer effects [5]. Studies have shown that oral feeding of capsaicin counters high-fat diet-induced obesity by inducing the conversion of energy-storing white fat to energy-expending brown fat to promote weight loss in obese mice [4]. However, to facilitate better compliance and adipocyte-specific delivery of capsaicin to induce thermogenesis, we developed 3D printed biodegradable capsaicin-loaded rod-shaped implant and propose to investigate the release and anti-obesity efficacy in a mouse model of diet-induced obesity. 3D printing, also known as additive manufacturing, has the potential to deliver personalized implants with complex designs and can elute the drug for prolonged periods of time.

Methods: 3D printed rod-shaped implants were fabricated utilizing thermoplastic extrusion-based 3D printing technology. Different blends in the ratio of 1:19, 1.5:18.5, and 2:18 of capsaicin and PCL respectively were utilized for 3D printing of rod-shaped implants. Various printing parameters such as printing temperature, pressure, speed, and extrusion time were optimized to obtain desired shape with good mechanical properties. The implants were characterized for their drug content, content uniformity, surface morphology, and drug-polymer miscibility. Release profiles were studied to determine the effect of infill density, drug loading, and printing temperature on the in vitro release of capsaicin. The studies were performed in phosphate-buffered saline (PBS) at 37°C under static conditions. At predetermined time intervals, the samples were collected and replaced with fresh medium. The amount of capsaicin released was determined by RP-HPLC with a C18 column (250x4.6mm, 5 µm), UV absorbance detector set at 228 nm and the mobile phase consisted of water and acetonitrile (40:60) at a flow rate of 1ml/min. The retention time of capsaicin was around 7.5 min with a total run time of 15 min. In vitro release was performed in triplicate and results were expressed as mean ±SEM.

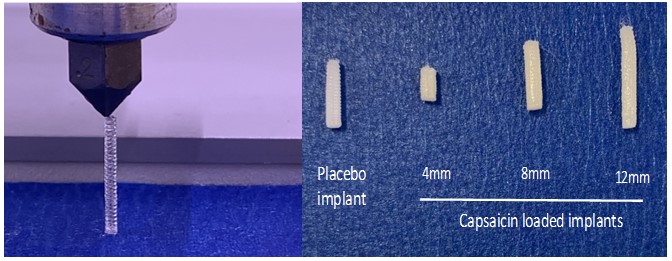

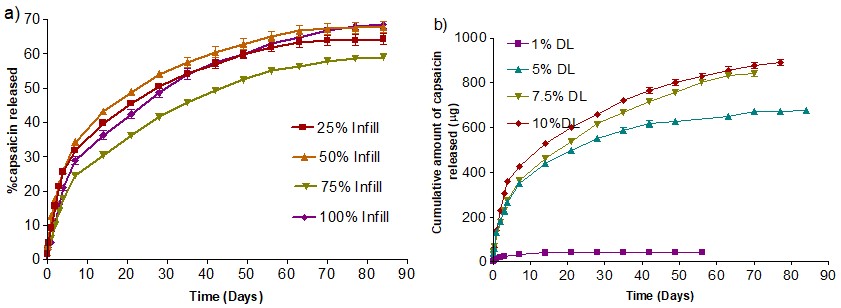

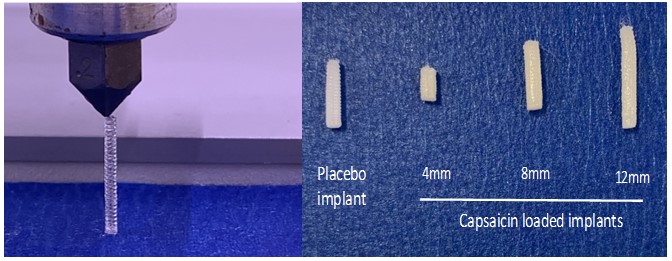

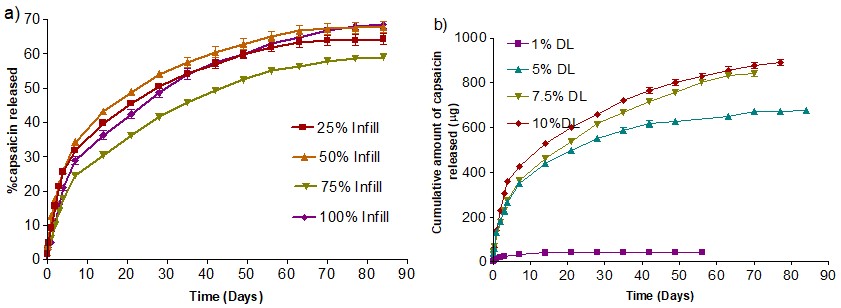

Results: Implants showed higher drug loading with uniform drug distribution (100±5%). The surface morphology of 3D printed implants showed a smooth and uniform surface without any macroscopic defects (Fig 1). Fig.2 showed the DSC curves of pure capsaicin, PCL, and 5% capsaicin-loaded implant. In DSC curves, the melting peak for capsaicin in mixture was lower than that of the drug alone, indicating the presence of drug in amorphous state. In vitro release studies showed sustained release of capsaicin (~70% release) for more than two months (Fig 3). In Fig. 3a, the percentage of capsaicin released from different infill densities did not show any significant effect on the in vitro release of capsaicin. Fig. 3b shows the cumulative amount of capsaicin released from different drug-loaded implants (1%, 5%, 7.5%, and 10% capsaicin-loaded implants). In all the drug loadings, the release was sustained for more than two months.

Conclusion: In the present study, a sustained release capsaicin-loaded implant system was fabricated to avoid clinical inconvenience and adverse effects of repeated intravenous administration of capsaicin. Capsaicin-loaded rod-shaped implants were successfully prepared by means of thermoplastic extrusion-based 3D printing technology. This technique has the potential to allow personalization of implantable devices for individual patients and conditions. The thermoanalytical studies suggest that capsaicin is in amorphous state in the PCL polymeric matrix. The in vitro release showed that biodegradable implants were adequate to prolong the release of capsaicin for more than 2 months. The surface morphology and mass loss studies of polymeric implants played an important role in the degradation and release profiles. Considering the simplicity of the technology, it can be easily transferred to a clinical setup, where implants could be printed on-demand to fulfill the patient needs for treating obesity and hyperlipidemia.

References: 1. The World Health Report 1997-Conquering Suffering, Enriching Humanity; World Health Organization: Geneva, 1998.

2. Hill, J. O.; Peters, J. C. Environment contributions to the obesity epidemic. Science 1998, 280, 1371−1374.

3. Obesity: Preventing and Managing the Global Epidemic; World Health Organization: Geneva, 2000.

4. Baskaran P, Markert L, Bennis J, Zimmerman L, Fox J, Thyagarajan B. Assessment of pharmacology, safety, and metabolic activity of capsaicin feeding in mice. Scientific reports. 2019 Jun 13;9(1):1-5.

5. Elmas C, Gezer C. Capsaicin and Its Effects on Body Weight. Journal of the American College of Nutrition. 2021 Jul 30:1-9.

Acknowledgements: We acknowledge the support of funding from the Presidential Award for Interdisciplinary Research (PAIR) grant.

Figure 1. Fabrication of capsaicin-loaded rod-shaped implants by means of thermoplastic extrusion-based 3D printing technology.

.jpg)

Figure 2. DSC curves of pure capsaicin, PCL polymer, and 5% capsaicin-loaded polymeric implant.

Figure 3. In vitro release of capsaicin from 3D printed implants a) printed with different infill densities (25%, 50%, 75%, and 100% infill); b) Cumulative amount of capsaicin released from different concentrations of drug-loaded implants (n=4)

Formulation and Delivery - Chemical - Drug Delivery

Category: Poster Abstract

(T0930-03-13) Preparation and Evaluation of 3D Printed Capsaicin-Loaded Rod-Shaped Implants for Treating Obesity and Hyperlipidemia

Tuesday, October 18, 2022

9:30 AM – 10:30 AM ET

- MA

Manjusha Annaji, MS

PhD student

Auburn University

Auburn, Alabama, United States - MA

Manjusha Annaji, MS

PhD student

Auburn University

Auburn, Alabama, United States

Presenting Author(s)

Main Author(s)

Purpose: Diet-induced obesity has become a serious global health problem associated with an increased risk of developing type-2 diabetes, hypertension, atherosclerosis, myocardial infarction, non-alcoholic fatty liver disease, chronic kidney disease, cerebrovascular disease, and cancer [1,2]. Currently, the FDA-approved therapeutic strategies for weight loss include Orlistat, Fenfluramine, and Lorcaserin, but some of them are delisted due to their severe adverse effects [3]. For example, Orlistat was issued a warning due to its serious gastrointestinal adverse effects, and liver failure. Other anti-obesity drugs such as fenfluramine and rimonabant are withdrawn from the market due to their severe side effects such as mood disorders and cardiovascular risks. As an alternative to anti-obesity drugs, bariatric surgery such as Sleeve gastrectomy and Roux-en-Y gastric surgery were found to be more effective. However, it is expensive and associated with an increased risk of post-surgical complications. Therefore, there is an urgent need to develop safe, effective, and personalized therapies for the early prevention and treatment of overweight and obesity. Capsaicin is the principal ingredient of natural chili peppers, responsible for its pungent flavor [4]. Many studies have revealed the beneficial effects of capsaicin such as anti-inflammatory, antioxidant, antiobesity, and anticancer effects [5]. Studies have shown that oral feeding of capsaicin counters high-fat diet-induced obesity by inducing the conversion of energy-storing white fat to energy-expending brown fat to promote weight loss in obese mice [4]. However, to facilitate better compliance and adipocyte-specific delivery of capsaicin to induce thermogenesis, we developed 3D printed biodegradable capsaicin-loaded rod-shaped implant and propose to investigate the release and anti-obesity efficacy in a mouse model of diet-induced obesity. 3D printing, also known as additive manufacturing, has the potential to deliver personalized implants with complex designs and can elute the drug for prolonged periods of time.

Methods: 3D printed rod-shaped implants were fabricated utilizing thermoplastic extrusion-based 3D printing technology. Different blends in the ratio of 1:19, 1.5:18.5, and 2:18 of capsaicin and PCL respectively were utilized for 3D printing of rod-shaped implants. Various printing parameters such as printing temperature, pressure, speed, and extrusion time were optimized to obtain desired shape with good mechanical properties. The implants were characterized for their drug content, content uniformity, surface morphology, and drug-polymer miscibility. Release profiles were studied to determine the effect of infill density, drug loading, and printing temperature on the in vitro release of capsaicin. The studies were performed in phosphate-buffered saline (PBS) at 37°C under static conditions. At predetermined time intervals, the samples were collected and replaced with fresh medium. The amount of capsaicin released was determined by RP-HPLC with a C18 column (250x4.6mm, 5 µm), UV absorbance detector set at 228 nm and the mobile phase consisted of water and acetonitrile (40:60) at a flow rate of 1ml/min. The retention time of capsaicin was around 7.5 min with a total run time of 15 min. In vitro release was performed in triplicate and results were expressed as mean ±SEM.

Results: Implants showed higher drug loading with uniform drug distribution (100±5%). The surface morphology of 3D printed implants showed a smooth and uniform surface without any macroscopic defects (Fig 1). Fig.2 showed the DSC curves of pure capsaicin, PCL, and 5% capsaicin-loaded implant. In DSC curves, the melting peak for capsaicin in mixture was lower than that of the drug alone, indicating the presence of drug in amorphous state. In vitro release studies showed sustained release of capsaicin (~70% release) for more than two months (Fig 3). In Fig. 3a, the percentage of capsaicin released from different infill densities did not show any significant effect on the in vitro release of capsaicin. Fig. 3b shows the cumulative amount of capsaicin released from different drug-loaded implants (1%, 5%, 7.5%, and 10% capsaicin-loaded implants). In all the drug loadings, the release was sustained for more than two months.

Conclusion: In the present study, a sustained release capsaicin-loaded implant system was fabricated to avoid clinical inconvenience and adverse effects of repeated intravenous administration of capsaicin. Capsaicin-loaded rod-shaped implants were successfully prepared by means of thermoplastic extrusion-based 3D printing technology. This technique has the potential to allow personalization of implantable devices for individual patients and conditions. The thermoanalytical studies suggest that capsaicin is in amorphous state in the PCL polymeric matrix. The in vitro release showed that biodegradable implants were adequate to prolong the release of capsaicin for more than 2 months. The surface morphology and mass loss studies of polymeric implants played an important role in the degradation and release profiles. Considering the simplicity of the technology, it can be easily transferred to a clinical setup, where implants could be printed on-demand to fulfill the patient needs for treating obesity and hyperlipidemia.

References: 1. The World Health Report 1997-Conquering Suffering, Enriching Humanity; World Health Organization: Geneva, 1998.

2. Hill, J. O.; Peters, J. C. Environment contributions to the obesity epidemic. Science 1998, 280, 1371−1374.

3. Obesity: Preventing and Managing the Global Epidemic; World Health Organization: Geneva, 2000.

4. Baskaran P, Markert L, Bennis J, Zimmerman L, Fox J, Thyagarajan B. Assessment of pharmacology, safety, and metabolic activity of capsaicin feeding in mice. Scientific reports. 2019 Jun 13;9(1):1-5.

5. Elmas C, Gezer C. Capsaicin and Its Effects on Body Weight. Journal of the American College of Nutrition. 2021 Jul 30:1-9.

Acknowledgements: We acknowledge the support of funding from the Presidential Award for Interdisciplinary Research (PAIR) grant.

Figure 1. Fabrication of capsaicin-loaded rod-shaped implants by means of thermoplastic extrusion-based 3D printing technology.

.jpg)

Figure 2. DSC curves of pure capsaicin, PCL polymer, and 5% capsaicin-loaded polymeric implant.

Figure 3. In vitro release of capsaicin from 3D printed implants a) printed with different infill densities (25%, 50%, 75%, and 100% infill); b) Cumulative amount of capsaicin released from different concentrations of drug-loaded implants (n=4)