Back

Purpose: The handling of many powders that are used in the nutraceutical industry can be challenging due to their poor flow properties, cohesiveness and stickiness. Therefore, glidants such as colloidal silicon dioxide are commonly added to nutraceutical powders to enhance their powder flow and reduce cohesion. Various grades of synthetic silicon dioxide are commonly used but they are not considered label-friendly. In the nutraceutical supplement sector, consumer desire for products containing natural and label-friendly ingredients has been growing. Hence, there is a need for efficient clean label natural excipients including glidants. In this study, the performance of a natural plant-based glidant and a commonly used synthetic glidant, Cab-o-sil M-5P were compared. Four model materials with different powder flow rates were evaluated for their physical and morphological properties.

Methods: Four model powder materials: caffeine anhydrous; guar gum; Starch 1500®, partially pregelatinized maize starch and StarCap®, superior flow maize starch were studied. Binary blends of glidant and each model powder were prepared at 1, 2 and 4% w/w inclusion levels by mixing for 3 minutes. The surface morphology of both glidants and the four model materials was examined using scanning electron microscopy (SEM) at 5 kv. Particle size distribution (PSD) was determined using a laser diffraction system, Malvern Scirocco 2000. Samples were measured at 2 bar and 50% feeding rate where the obscuration was maintained between 5 – 10 %. Powder flow of the pure materials and the binary blends were characterized in terms of flowability index and angle of repose using Flodex™ instrument and Hosokawa Micron Powder Tester (PT-X). Flodex testing was performed following Hanson’s method1. The smallest disk hole in millimeters to allow the powder to fall through three consecutive times is considered as the flowability index. The smaller the flowability index, the better the flow. Flodex testing was performed for all binary blends (1, 2 and 4% w/w) while the angle of repose measurements was determined only for the 1% w/w inclusion level (n=2).

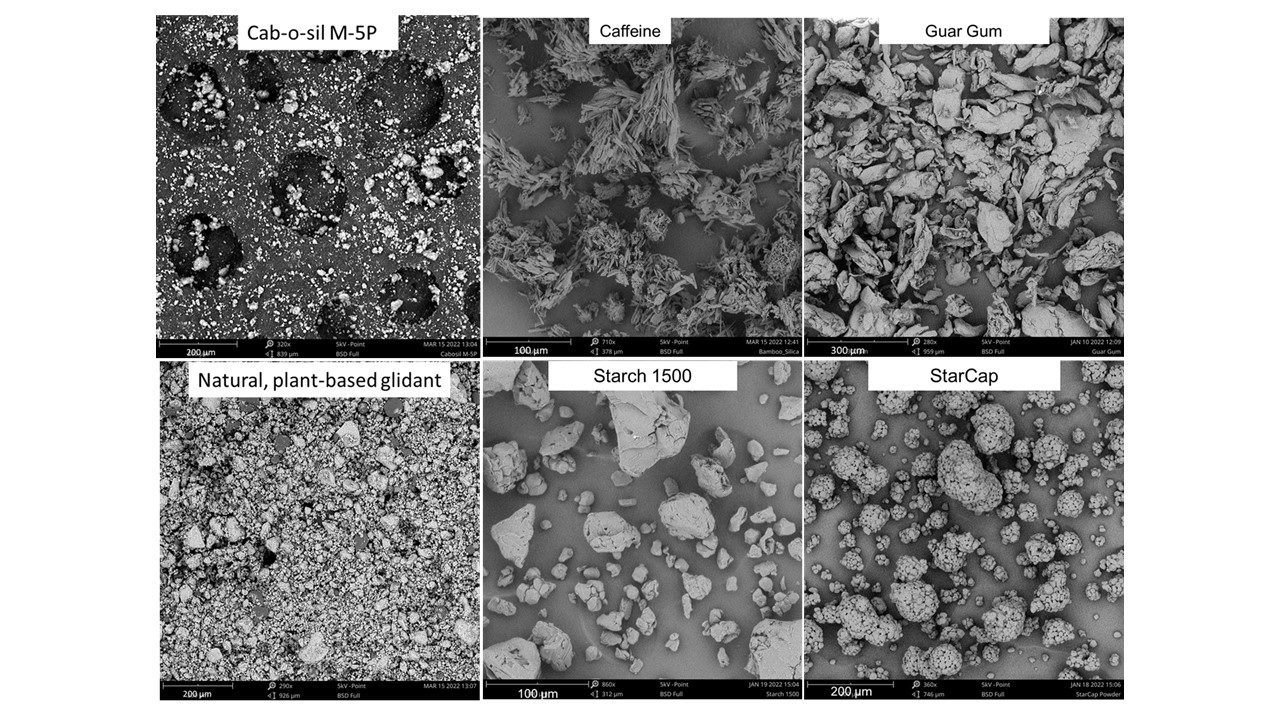

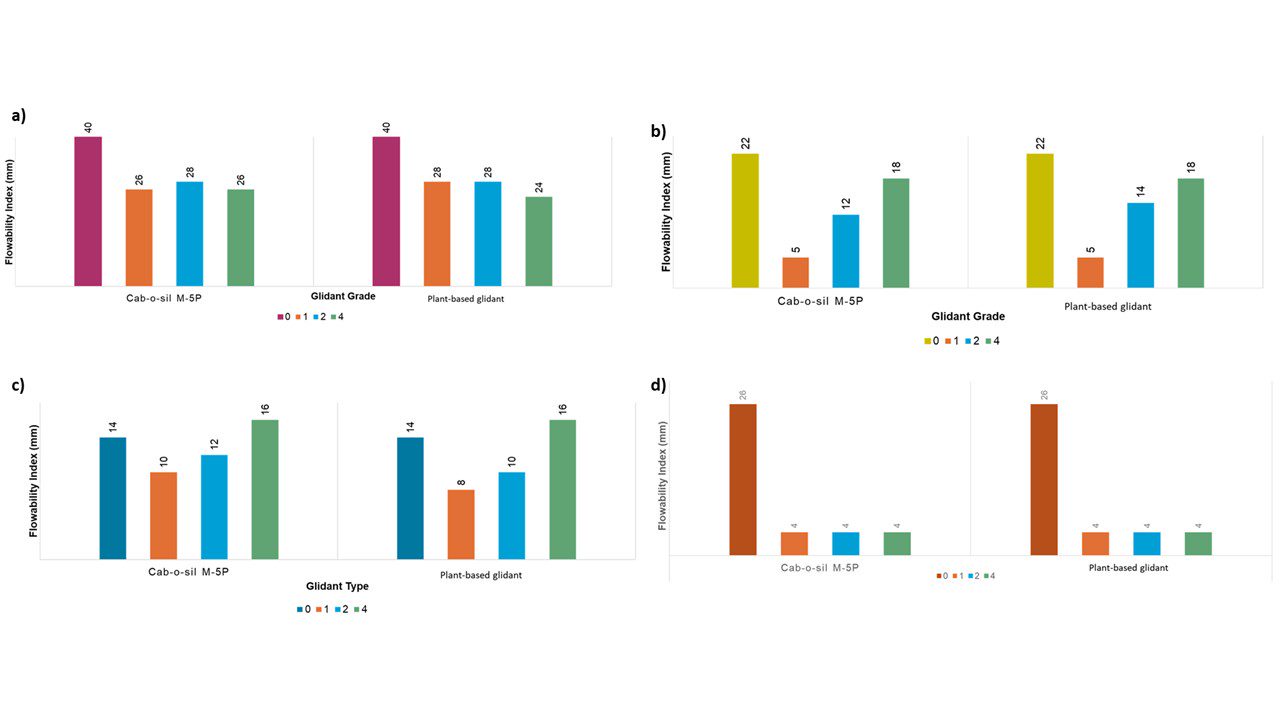

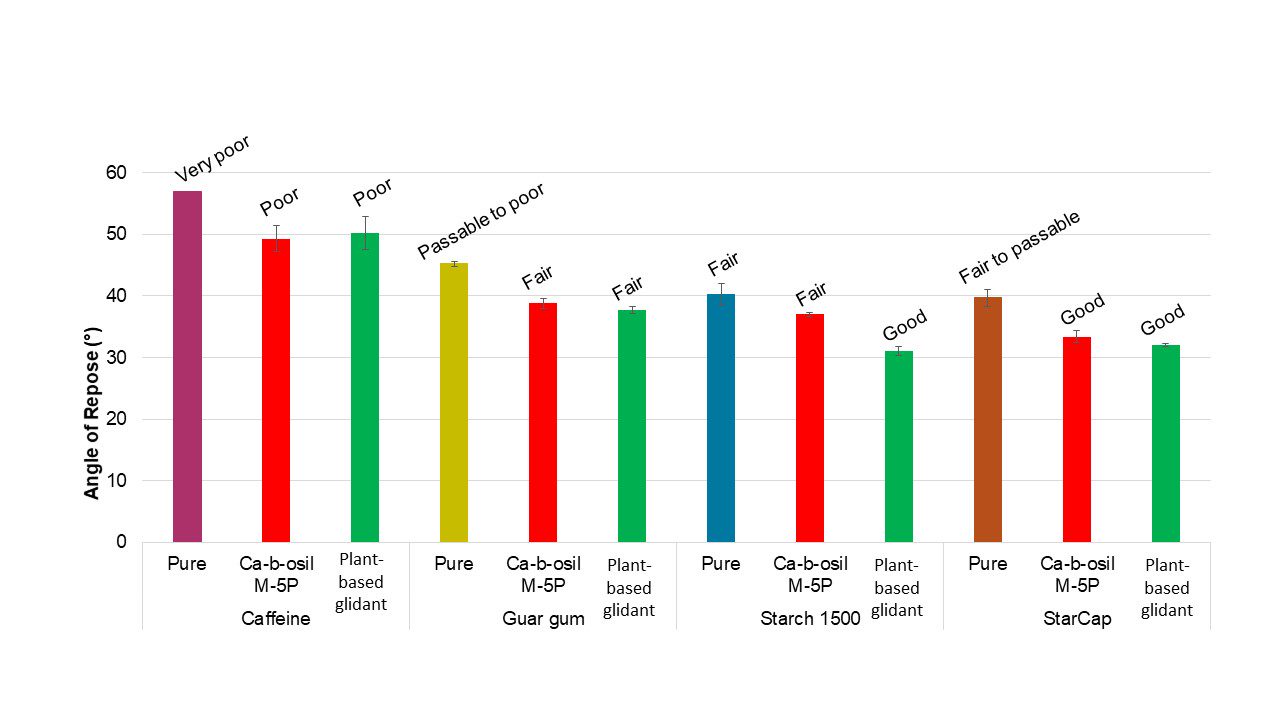

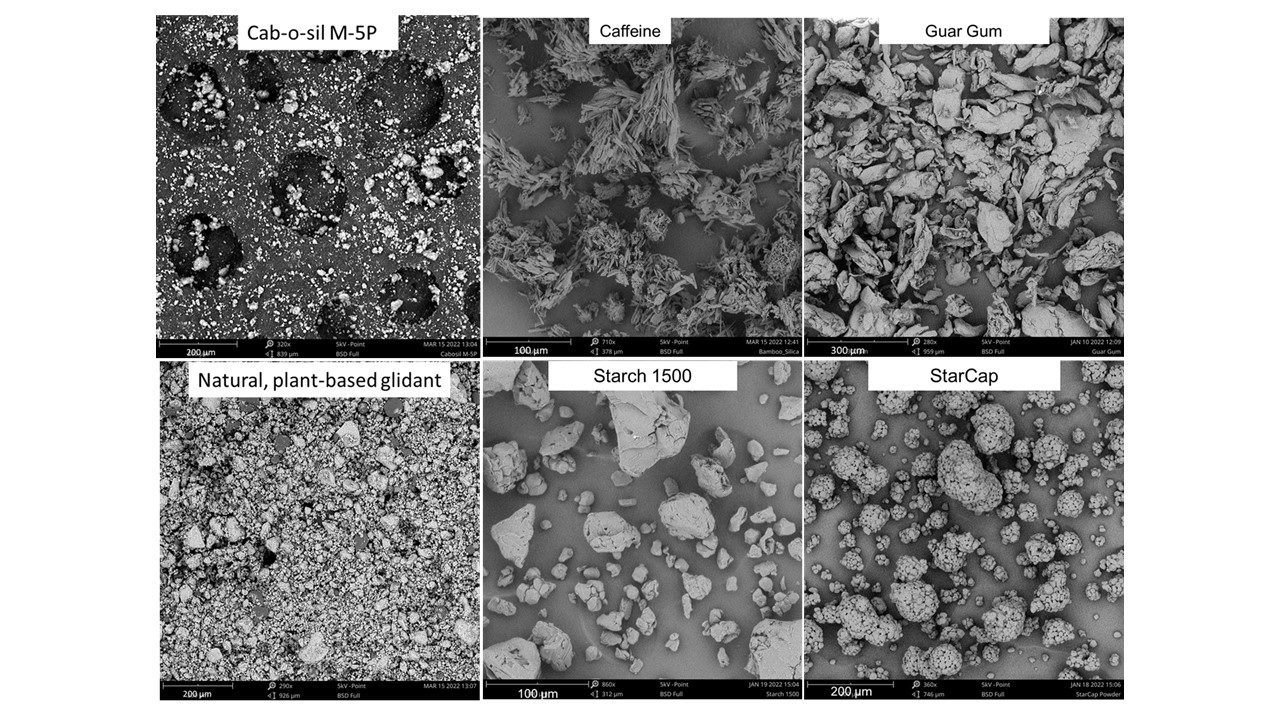

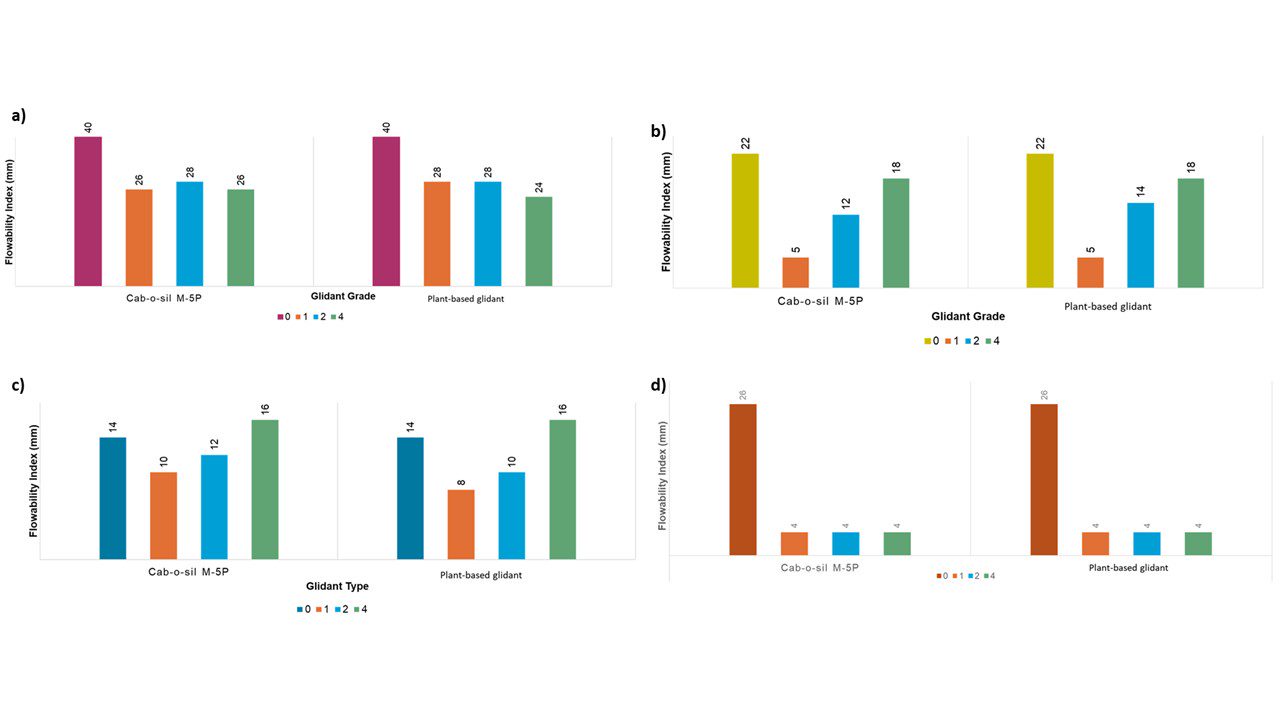

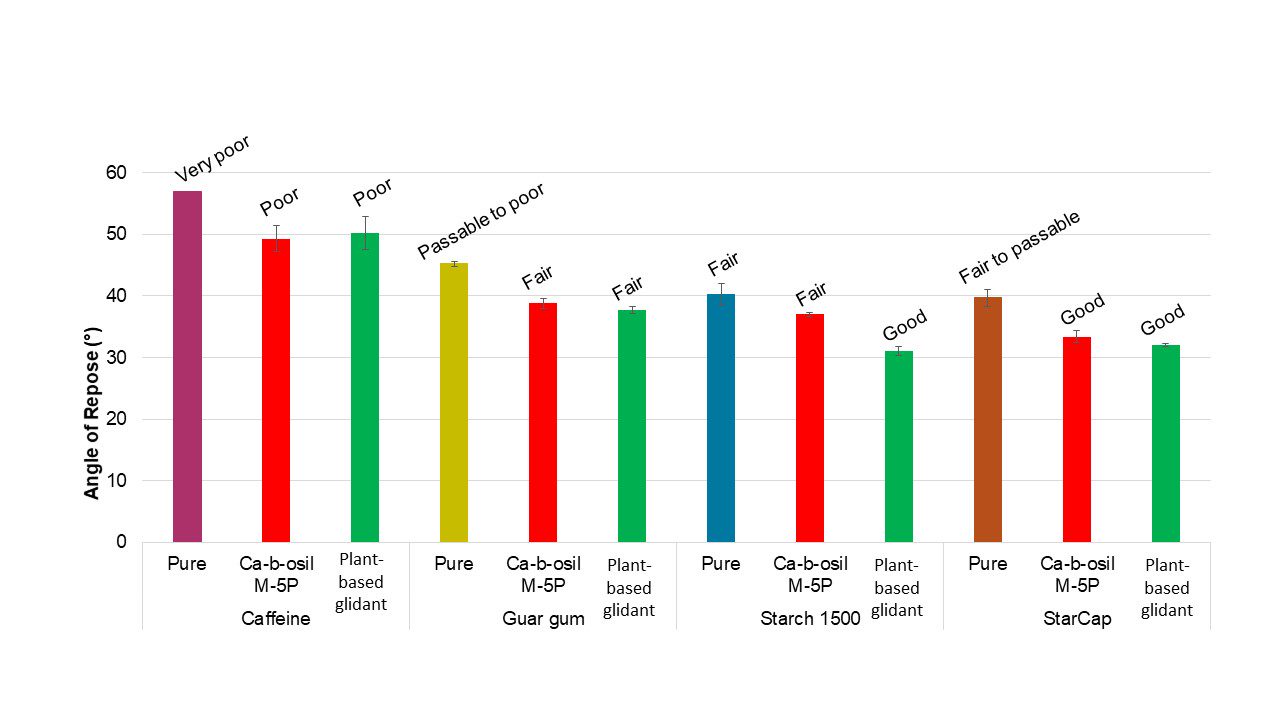

Results: The SEM images (Figure 1) depicted that the plant-based glidant and Cab-o-sil M-5P had mostly round morphology with small geometric particle size. The four model powders were shown to have varying surface morphology. Caffeine anhydrous had needle crystalline structure in an aggregated form. Guar gum had fibrous nature while Starch 1500 had a non-uniform shape with non-porous structure. On the other hand, StarCap had spherical shape that demonstrated a porous structure. The plant-based glidant had a comparable average particle size to Cab-o-sil M-5P. Among the four model powders, caffeine anhydrous had the smallest average particle size of 7.0 µm and Starch 1500 had the largest size of 97.0 µm. StarCap and guar gum had average particle sizes of 73.4 and 78.9 µm, respectively. The flowability indices of the four model powders were inversely proportional to their average particle size. Caffeine anhydrous with the smallest particle size had the highest flowability index of 40. This was followed by StarCap, guar gum and Starch 1500 with flowability indices of 26, 22 and 14, respectively. The addition of the plant-based glidant (Figure 2) at 1% w/w resulted in comparable enhancement in powder flow to Cab-o-sil M-5P for all four model powders. Increasing the glidant inclusion level at 4% did not have much affect the flowability indices of caffeine anhydrous and StarCap, but significantly deteriorated the powder flow of guar gum and Starch 1500 as shown in Figure 2. Similar to Cab-o-sil M-5P the plant-based glidant enhanced the angle of repose powder flow property of all four model powders (Figure 3). Needle-structured caffeine anhydrous had the highest angle of repose of 56.9°, indicating a very poor powder flow property based on the USP < 1174 > angle of repose classification2. The two glidant grades enhanced the powder flow of caffeine from the very poor to the poor category. The angle of repose for guar gum was improved from passable/poor to fair whereas StarCap was enhanced from fair/passable to good. Starch 1500 presented the only discrepancy between the two glidant grades with the plant-based grade enhancing the powder flow of Starch 1500 from fair to good rather than remaining fair for Cab-o-sil M-5P.

Conclusion: The natural, plant-based glidant enhanced the flow properties of all tested model powders mainly at 1% w/w inclusion level. The plant-based glidant demonstrated the same efficiency as one of the most commonly used synthetic glidants, Cab-o-sil M-5P. Hence, it is concluded that a clean-label natural glidant can replace the use of synthetic glidants in the nutraceutical sector, increasing consumers satisfaction.

References: 1. https://files.hansonresearch.com/wp-content/uploads/2019/06/21101000-E-Flodex-Operation-Manual.pdf

2. https://www.usp.org/sites/default/files/usp/document/harmonization/gen-chapter/g05_pf_30_6_2004.pdf

Figure 1: SEM Images Revealing the Surface Morphology for the Study Materials

Figure 2: Effect of the Glidant Grade and the Inclusion Level on the Flowability Index of a) Caffeine Anhydrous, b) Guar Gum, c) Starch 1500 and d) StarCap

Figure 3: Effect of Plant-Based Glidant and Cab-o-sil M-5P on the Angle of Repose of Four Model Powders. The angle of repose USP powder flow category for each sample (average ±standard deviation) is summarized on the top of each charted column.

Formulation and Delivery - Chemical - Formulation

Category: Poster Abstract

(M1430-03-14) The Effect of a Clean-Label, Plant-Based Natural Glidant on the Flow Properties of Multiple Model Powders Compared to a Synthetic Glidant

Monday, October 17, 2022

2:30 PM – 3:30 PM ET

- SA

Sarah Aboelela, Ph.D.

Colorcon, Inc.

Harleysville, Pennsylvania, United States - SA

Sarah Aboelela, Ph.D.

Colorcon, Inc.

Harleysville, Pennsylvania, United States

Presenting Author(s)

Main Author(s)

Purpose: The handling of many powders that are used in the nutraceutical industry can be challenging due to their poor flow properties, cohesiveness and stickiness. Therefore, glidants such as colloidal silicon dioxide are commonly added to nutraceutical powders to enhance their powder flow and reduce cohesion. Various grades of synthetic silicon dioxide are commonly used but they are not considered label-friendly. In the nutraceutical supplement sector, consumer desire for products containing natural and label-friendly ingredients has been growing. Hence, there is a need for efficient clean label natural excipients including glidants. In this study, the performance of a natural plant-based glidant and a commonly used synthetic glidant, Cab-o-sil M-5P were compared. Four model materials with different powder flow rates were evaluated for their physical and morphological properties.

Methods: Four model powder materials: caffeine anhydrous; guar gum; Starch 1500®, partially pregelatinized maize starch and StarCap®, superior flow maize starch were studied. Binary blends of glidant and each model powder were prepared at 1, 2 and 4% w/w inclusion levels by mixing for 3 minutes. The surface morphology of both glidants and the four model materials was examined using scanning electron microscopy (SEM) at 5 kv. Particle size distribution (PSD) was determined using a laser diffraction system, Malvern Scirocco 2000. Samples were measured at 2 bar and 50% feeding rate where the obscuration was maintained between 5 – 10 %. Powder flow of the pure materials and the binary blends were characterized in terms of flowability index and angle of repose using Flodex™ instrument and Hosokawa Micron Powder Tester (PT-X). Flodex testing was performed following Hanson’s method1. The smallest disk hole in millimeters to allow the powder to fall through three consecutive times is considered as the flowability index. The smaller the flowability index, the better the flow. Flodex testing was performed for all binary blends (1, 2 and 4% w/w) while the angle of repose measurements was determined only for the 1% w/w inclusion level (n=2).

Results: The SEM images (Figure 1) depicted that the plant-based glidant and Cab-o-sil M-5P had mostly round morphology with small geometric particle size. The four model powders were shown to have varying surface morphology. Caffeine anhydrous had needle crystalline structure in an aggregated form. Guar gum had fibrous nature while Starch 1500 had a non-uniform shape with non-porous structure. On the other hand, StarCap had spherical shape that demonstrated a porous structure. The plant-based glidant had a comparable average particle size to Cab-o-sil M-5P. Among the four model powders, caffeine anhydrous had the smallest average particle size of 7.0 µm and Starch 1500 had the largest size of 97.0 µm. StarCap and guar gum had average particle sizes of 73.4 and 78.9 µm, respectively. The flowability indices of the four model powders were inversely proportional to their average particle size. Caffeine anhydrous with the smallest particle size had the highest flowability index of 40. This was followed by StarCap, guar gum and Starch 1500 with flowability indices of 26, 22 and 14, respectively. The addition of the plant-based glidant (Figure 2) at 1% w/w resulted in comparable enhancement in powder flow to Cab-o-sil M-5P for all four model powders. Increasing the glidant inclusion level at 4% did not have much affect the flowability indices of caffeine anhydrous and StarCap, but significantly deteriorated the powder flow of guar gum and Starch 1500 as shown in Figure 2. Similar to Cab-o-sil M-5P the plant-based glidant enhanced the angle of repose powder flow property of all four model powders (Figure 3). Needle-structured caffeine anhydrous had the highest angle of repose of 56.9°, indicating a very poor powder flow property based on the USP < 1174 > angle of repose classification2. The two glidant grades enhanced the powder flow of caffeine from the very poor to the poor category. The angle of repose for guar gum was improved from passable/poor to fair whereas StarCap was enhanced from fair/passable to good. Starch 1500 presented the only discrepancy between the two glidant grades with the plant-based grade enhancing the powder flow of Starch 1500 from fair to good rather than remaining fair for Cab-o-sil M-5P.

Conclusion: The natural, plant-based glidant enhanced the flow properties of all tested model powders mainly at 1% w/w inclusion level. The plant-based glidant demonstrated the same efficiency as one of the most commonly used synthetic glidants, Cab-o-sil M-5P. Hence, it is concluded that a clean-label natural glidant can replace the use of synthetic glidants in the nutraceutical sector, increasing consumers satisfaction.

References: 1. https://files.hansonresearch.com/wp-content/uploads/2019/06/21101000-E-Flodex-Operation-Manual.pdf

2. https://www.usp.org/sites/default/files/usp/document/harmonization/gen-chapter/g05_pf_30_6_2004.pdf

Figure 1: SEM Images Revealing the Surface Morphology for the Study Materials

Figure 2: Effect of the Glidant Grade and the Inclusion Level on the Flowability Index of a) Caffeine Anhydrous, b) Guar Gum, c) Starch 1500 and d) StarCap

Figure 3: Effect of Plant-Based Glidant and Cab-o-sil M-5P on the Angle of Repose of Four Model Powders. The angle of repose USP powder flow category for each sample (average ±standard deviation) is summarized on the top of each charted column.