Back

Purpose: A potential strategy to increase the bioavailability of a poorly water-soluble drug is the use of ASDs. As during early drug development, the available API amount is typically low (mostly less than 1 g), ASD screening on small batch sizes is an asset. In current study, the minimal required batch size needed on the PROCEPT spray dryer was investigated to obtain (1) sufficient material for solid state characterization, and (2) an indicative yield for a larger scale process.

Methods: 1. Materials - A poorly water-soluble API was dissolved in ethanol. Polyvinyl pyrrolidone (PVP) K30 was used as carrier in a 1/1 ratio of API/polymer (%w/w). Furthermore, two different solid loads were evaluated (2% and 4% (w/w)). 2. Spray drying - Spray drying of the ethanol-based formulations was executed on the PROCEPT spray dryer equipped with a medium sized cyclone. Dosing of the liquid formulation was set at 3.3 g/min. A bi-fluid nozzle with orifice of 0.8 mm was used. Nozzle atomization air was set at 4 L/min. Additionally, inlet airflow and inlet temperature was fixed at 0.3 m³/min and 100 °C, respectively. A cyclone gas flow of 200 L/min was applied. 3. Solid state characterization 3.1 mDSC - A sample (≤ 5 mg) was placed in a Tzero pan/Tzero hermetic and sealed before analysis with a Q2000 DSC (TA instruments) connected to a refrigerated cooling system unit and purged with 50 mL/min of inert dry nitrogen gas. The pan was equilibrated at a temperature of 25 °C before heating to 200 °C at an underlying heating rate of 2 °C/min. During the heating, the temperature was modulated over a period of 40 s with an amplitude of 0.64 °C. 3.2 XRPD - XRPD analysis were carried out using an automated Aeris diffractometer (PANalytical, malvern) with a Cu tube (Kα λ=1.5418Å) with the generator of 40 kV and 15 mA. Samples (≤ 20 mg) were applied on spinning zero background sample holders. Measurements were performed in a continuous scan mode from 4° to 40° with 0.0217° step size and 500 s per step counting time.

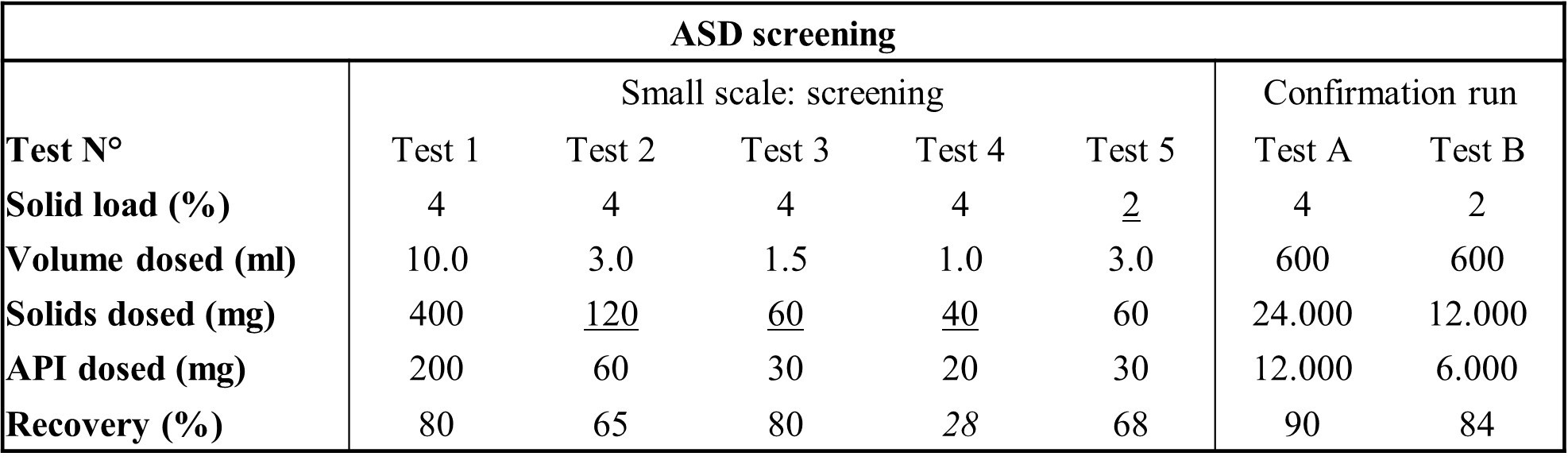

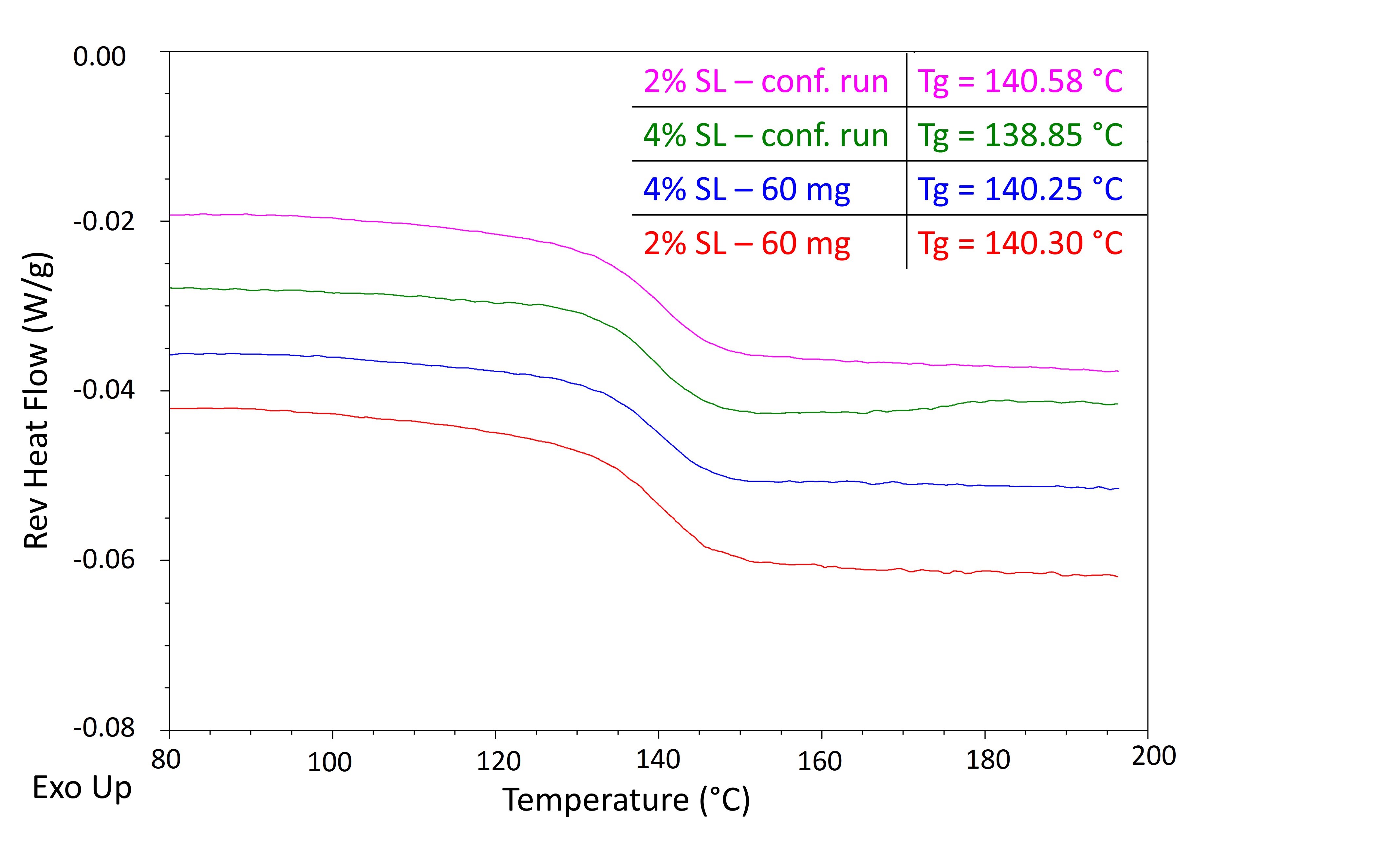

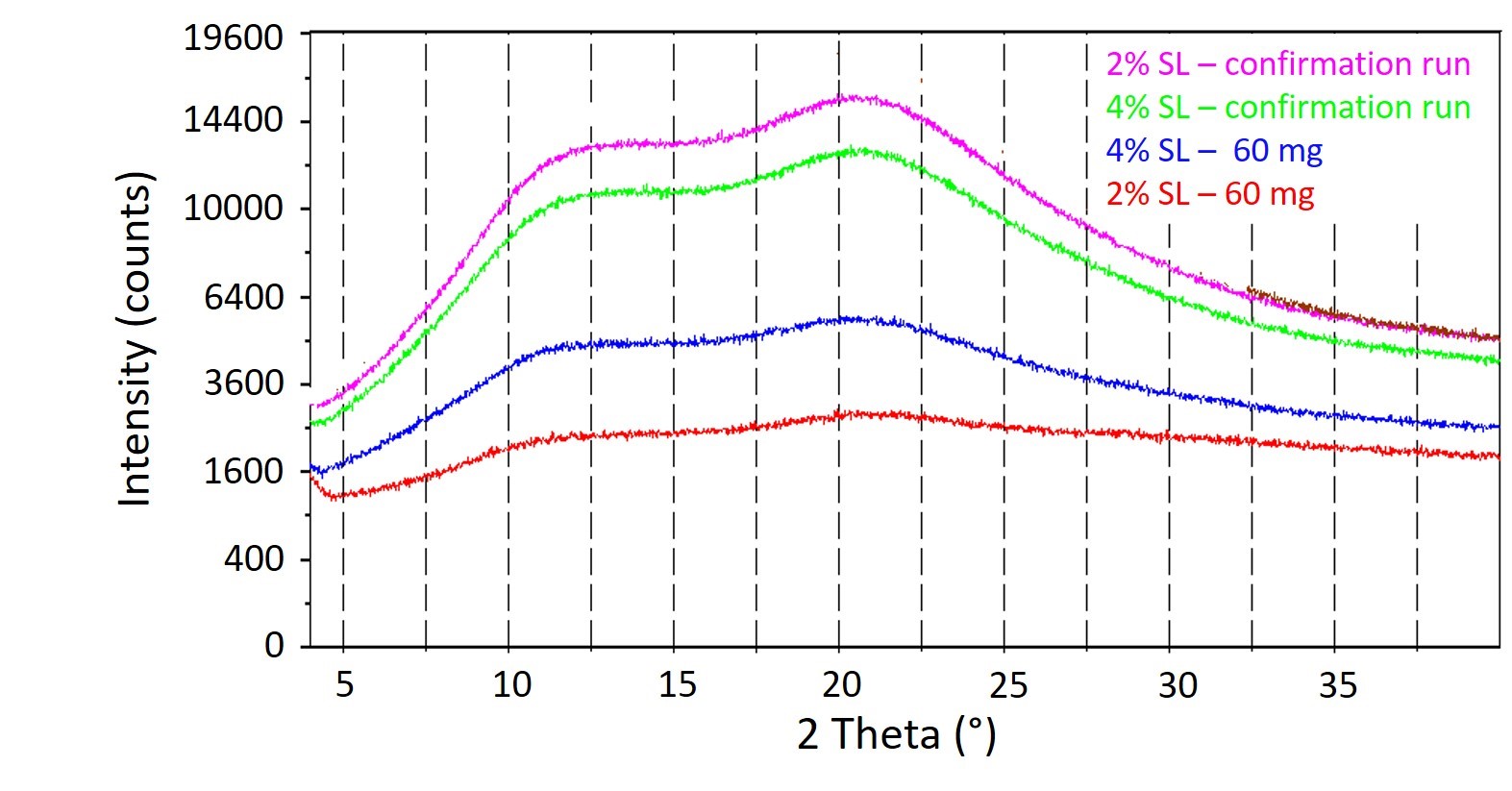

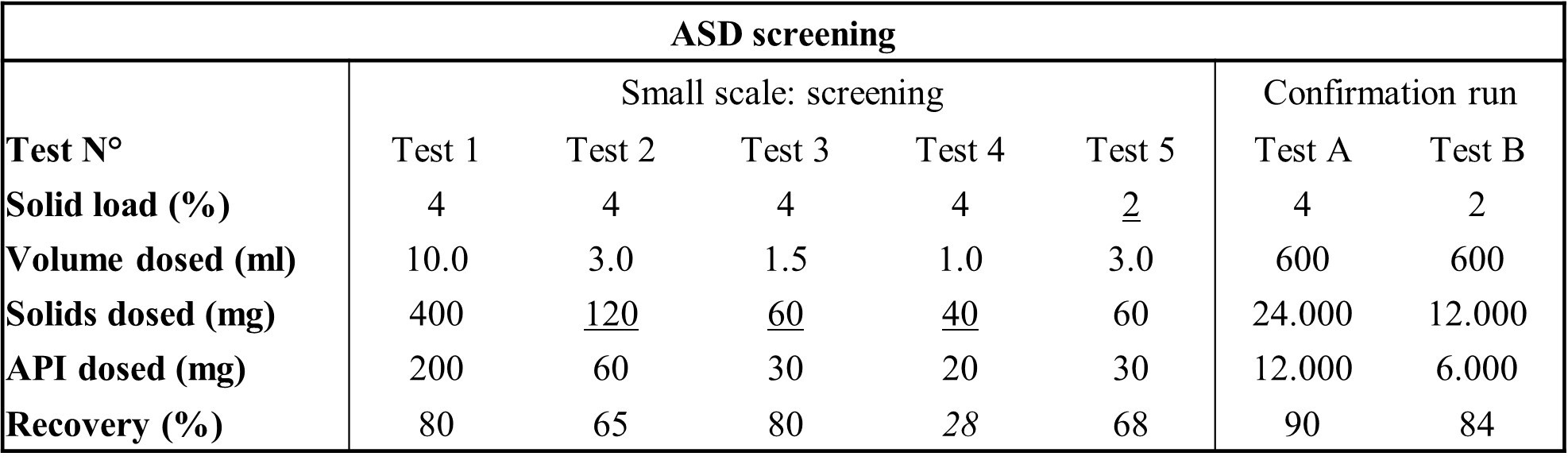

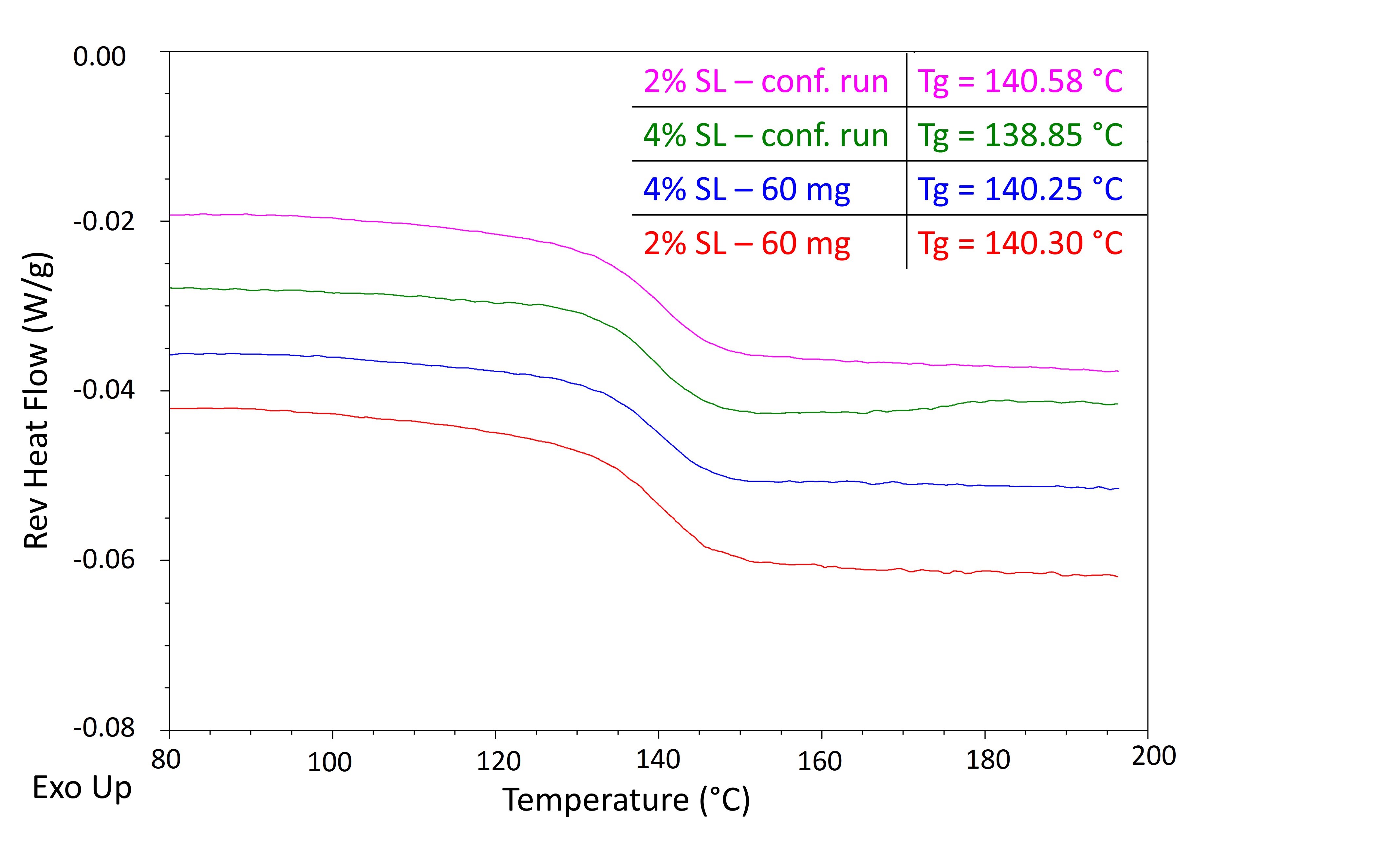

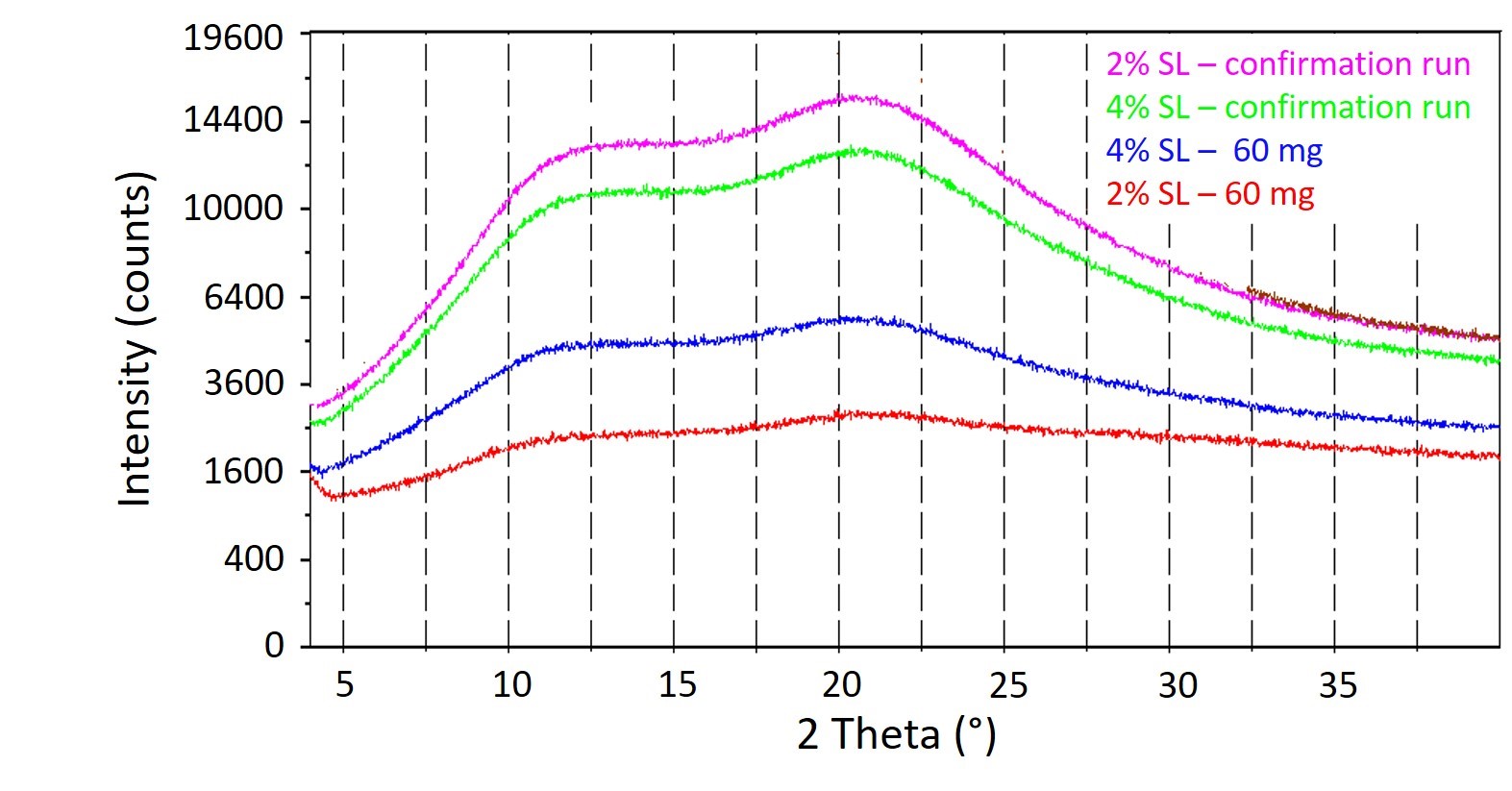

Results: To investigate the required minimal batch size to obtain a representative spray drying process, a stepwise decrease in the total amount of solids dosed was performed for a 4%(w/w) formulation (Test 1 to 4, Fig.1). Batch sizes of 400 mg, 120 mg and 60 mg resulted in a product recovery ≥ 65%, whereas a profound decrease in product recovery was observed when applying a batch size of 40 mg solids (28%). This decrease in product recovery was explained by a relative increase of product loss on the glass wall of the equipment. The effect of a decrease in solid load on the product recovery was evaluated at a constant batch size of 60 mg (solid load of 2% instead of 4% (w/w)) (test 3 vs. test 5, Fig. 1). Although the processing time was doubled for test 5, a high and comparable process recovery was observed for both tests. A large scale production was performed to confirm that the product obtained via small scale spray drying (60 mg of total solids) was representative. For both solid loads, 2% and 4% (w/w), a 3 h confirmation run was performed corresponding to 12 and 24 g of total solids dosed, respectively (Fig. 1). Both confirmation runs (A and B) resulted in high product recoveries of 90% and 84%, respectively. This increase in recovery was caused by a relative decrease of product losses deposed on the glass wall of the equipment. Analyses with mDSC (Fig. 2) and XRPD (Fig. 3) showed that neither the solid load, nor the batch size had affected the solid state of the final product. For all formulations, a homogeneous amorphous system was obtained with a Tg of 140 °C. Small amounts of spray-dried material are required for characterization via mDSC and XRPD. It was shown that proper recoveries were obtained during the small scale screening tests, and consequently, sufficient material was collected to evaluate the API stability by the selected polymer.

Conclusion: This study demonstrated that on a PROCEPT spray dryer small batch sizes (60 mg solids) were processable, as product recoveries ≥ 65% were acquired. The amount of spray-dried material was sufficient for solid state characterization. Results of the small batches were representative for long processing runs.

Schematic overview of small-scale test runs (test 1 to 5), and large-scale confirmation runs (test A and B).

mDSC results of tests 3 and 5 produced at small-scale (blue-red) and at large-scale (green-pink) – reversed heat flow.

XRPD analysis of tests 3 and 5 produced at small-scale (blue-red) and large-scale (pink-green).

Formulation and Delivery - Chemical - Formulation

Category: Poster Abstract

(M1030-03-17) Spray Drying of Amorphous Solid Dispersions (ASDs): Small Scale Screening of Batches containing Less than 50 mg API

Monday, October 17, 2022

10:30 AM – 11:30 AM ET

- FV

Filip Van der Gucht, MS

Procept

Zele, Oost-Vlaanderen, Belgium - ED

Elien De Coninck, Ph.D.

Xedev

Zele, Oost-Vlaanderen, Belgium

Presenting Author(s)

Main Author(s)

Purpose: A potential strategy to increase the bioavailability of a poorly water-soluble drug is the use of ASDs. As during early drug development, the available API amount is typically low (mostly less than 1 g), ASD screening on small batch sizes is an asset. In current study, the minimal required batch size needed on the PROCEPT spray dryer was investigated to obtain (1) sufficient material for solid state characterization, and (2) an indicative yield for a larger scale process.

Methods: 1. Materials - A poorly water-soluble API was dissolved in ethanol. Polyvinyl pyrrolidone (PVP) K30 was used as carrier in a 1/1 ratio of API/polymer (%w/w). Furthermore, two different solid loads were evaluated (2% and 4% (w/w)). 2. Spray drying - Spray drying of the ethanol-based formulations was executed on the PROCEPT spray dryer equipped with a medium sized cyclone. Dosing of the liquid formulation was set at 3.3 g/min. A bi-fluid nozzle with orifice of 0.8 mm was used. Nozzle atomization air was set at 4 L/min. Additionally, inlet airflow and inlet temperature was fixed at 0.3 m³/min and 100 °C, respectively. A cyclone gas flow of 200 L/min was applied. 3. Solid state characterization 3.1 mDSC - A sample (≤ 5 mg) was placed in a Tzero pan/Tzero hermetic and sealed before analysis with a Q2000 DSC (TA instruments) connected to a refrigerated cooling system unit and purged with 50 mL/min of inert dry nitrogen gas. The pan was equilibrated at a temperature of 25 °C before heating to 200 °C at an underlying heating rate of 2 °C/min. During the heating, the temperature was modulated over a period of 40 s with an amplitude of 0.64 °C. 3.2 XRPD - XRPD analysis were carried out using an automated Aeris diffractometer (PANalytical, malvern) with a Cu tube (Kα λ=1.5418Å) with the generator of 40 kV and 15 mA. Samples (≤ 20 mg) were applied on spinning zero background sample holders. Measurements were performed in a continuous scan mode from 4° to 40° with 0.0217° step size and 500 s per step counting time.

Results: To investigate the required minimal batch size to obtain a representative spray drying process, a stepwise decrease in the total amount of solids dosed was performed for a 4%(w/w) formulation (Test 1 to 4, Fig.1). Batch sizes of 400 mg, 120 mg and 60 mg resulted in a product recovery ≥ 65%, whereas a profound decrease in product recovery was observed when applying a batch size of 40 mg solids (28%). This decrease in product recovery was explained by a relative increase of product loss on the glass wall of the equipment. The effect of a decrease in solid load on the product recovery was evaluated at a constant batch size of 60 mg (solid load of 2% instead of 4% (w/w)) (test 3 vs. test 5, Fig. 1). Although the processing time was doubled for test 5, a high and comparable process recovery was observed for both tests. A large scale production was performed to confirm that the product obtained via small scale spray drying (60 mg of total solids) was representative. For both solid loads, 2% and 4% (w/w), a 3 h confirmation run was performed corresponding to 12 and 24 g of total solids dosed, respectively (Fig. 1). Both confirmation runs (A and B) resulted in high product recoveries of 90% and 84%, respectively. This increase in recovery was caused by a relative decrease of product losses deposed on the glass wall of the equipment. Analyses with mDSC (Fig. 2) and XRPD (Fig. 3) showed that neither the solid load, nor the batch size had affected the solid state of the final product. For all formulations, a homogeneous amorphous system was obtained with a Tg of 140 °C. Small amounts of spray-dried material are required for characterization via mDSC and XRPD. It was shown that proper recoveries were obtained during the small scale screening tests, and consequently, sufficient material was collected to evaluate the API stability by the selected polymer.

Conclusion: This study demonstrated that on a PROCEPT spray dryer small batch sizes (60 mg solids) were processable, as product recoveries ≥ 65% were acquired. The amount of spray-dried material was sufficient for solid state characterization. Results of the small batches were representative for long processing runs.

Schematic overview of small-scale test runs (test 1 to 5), and large-scale confirmation runs (test A and B).

mDSC results of tests 3 and 5 produced at small-scale (blue-red) and at large-scale (green-pink) – reversed heat flow.

XRPD analysis of tests 3 and 5 produced at small-scale (blue-red) and large-scale (pink-green).