Back

O&M and Asset Management

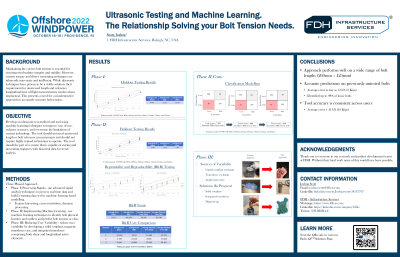

Ultrasonics and machine learning. The relationship solving your bolt tension needs.

Tuesday, October 18, 2022

Akash Nikam, PE

Research Engineer III

FDH Infrastructure Services, LLC

Raleigh, North Carolina

Presenter(s)

Presentation Description: Offshore wind turbines have unique maintenance challenges due to their environmental conditions and location, demonstrating a need for preventative maintenance to reduce costs associated with maintaining these structures. Like onshore turbines, maintaining correct flange bolt tension is essential to ensuring integrity and stability. Current torque- and direct-tensioning techniques are insufficient as bolt tension is unknown, and historical data is qualitative rather than quantitative. Existing ultrasound methods require unstressed bolt length measurements, making it difficult to predict tension on an existing structure’s bolts.

The proposed approach uses the relationship between longitudinal and shear wave time of flights (ToFs) to predict the bolt tension without requiring unstressed measurements or reference signals. Advanced machine learning-based modeling ensures quality data is collected with minimal technician training and offers interpolative/extrapolative predictions on previously untested bolts. All data is stored for future reference enabling preventative maintenance. Repeatability studies using the proposed method resulted in an average error of 10.28 Kips, and 98% of the tension predictions had less than 10% error (relative to yield stress). For example, an M42 bolt resulted in 40.8 MPa or 5.9 Ksi. This novel approach can reduce labor costs, testing time, and heavy equipment requirements while improving tension prediction accuracy by a factor of three or more.

The proposed approach uses the relationship between longitudinal and shear wave time of flights (ToFs) to predict the bolt tension without requiring unstressed measurements or reference signals. Advanced machine learning-based modeling ensures quality data is collected with minimal technician training and offers interpolative/extrapolative predictions on previously untested bolts. All data is stored for future reference enabling preventative maintenance. Repeatability studies using the proposed method resulted in an average error of 10.28 Kips, and 98% of the tension predictions had less than 10% error (relative to yield stress). For example, an M42 bolt resulted in 40.8 MPa or 5.9 Ksi. This novel approach can reduce labor costs, testing time, and heavy equipment requirements while improving tension prediction accuracy by a factor of three or more.

Learning Objectives:

- Understand how machine learning can be applied to bolt tension measurements

- Understand the bi-wave approach to bolt tension measurements

- Understand how a bi-wave approach overcomes the limitations of current NDT approaches to bolt tension measurements