Back

O&M and Asset Management

Enhanced Lightning Protection for Wind Turbine Blades

Tuesday, October 18, 2022

Neal Fine, n/a

CEO

Arctura, Inc.

South Kingstown, Rhode Island

Presenter(s)

Presentation Description: Lightning damage stubbornly remains a major O&M expense for owner-operators in cost and frequency. Damage such as blade skin punctures, shell delamination, split trailing edges, and occasionally catastrophic damage are costly to repair and cause downtime.

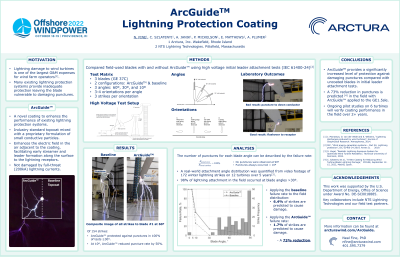

Most wind turbines come equipped with a lightning protection system, typically consisting of a set of metal disk receptors mounted flush to the surface of the blade and electrically connected to ground via a down conductor inside the blade. When the system works well during a strike, a leader from a receptor connects with a downward leader from the cloud, and the charge is safely transmitted to ground. However, the streamers that initiate inside the blade often win the race to connect with the lightning leader, resulting in punctures and other blade damage.

Arctura’s new ArcGuide™ blade coating improves the effectiveness of the surface-mounted lightning receptors, making it more likely that lightning will attach safely to the existing lightning protection system and less likely that it will attach directly to the down conductor or other internal blade components. In this presentation, we will review the genesis of the concept, the development and validation process, and we will review our ongoing wind farm field tests.

Most wind turbines come equipped with a lightning protection system, typically consisting of a set of metal disk receptors mounted flush to the surface of the blade and electrically connected to ground via a down conductor inside the blade. When the system works well during a strike, a leader from a receptor connects with a downward leader from the cloud, and the charge is safely transmitted to ground. However, the streamers that initiate inside the blade often win the race to connect with the lightning leader, resulting in punctures and other blade damage.

Arctura’s new ArcGuide™ blade coating improves the effectiveness of the surface-mounted lightning receptors, making it more likely that lightning will attach safely to the existing lightning protection system and less likely that it will attach directly to the down conductor or other internal blade components. In this presentation, we will review the genesis of the concept, the development and validation process, and we will review our ongoing wind farm field tests.

Learning Objectives:

- Upon completion, participant will be able to describe the impact that lightning has on wind turbine blades

- Upon completion, participant will be able to describe how the wind turbine lightning protection works and how it fails

- Upon completion, participant will be able to describe how Arctura's enhanced lightning protection blade coating works